Dairy farming is a 24/7 job. There is no such thing as a “day off” when 300+ cows need to be milked twice every day. With these time limitations in mind, it is easy to see why it took Neil McIsaac III, a fifth generation dairy farmer, six years to build his dream truck – a 1969 Peterbilt 358A hay truck with a tilt hood. Starting out in rough shape, after sitting for over a decade in a field, this project was a huge labor of love, and every single part has a story – just ask Neil, he’ll tell you. And even though one guy skipped town and another retired during the build, in the end, it got done – and Neil couldn’t be happier.

For five generations, Neil’s family has dairy farmed in and around the beautiful and rural area of Marin County, just north of San Francisco. Previous generations had farms in Olema, Nicasio and Novato, and six months after Neil was born in 1973, his family moved to their present location in Tomales – a rural suburb west of Petaluma near the ocean. The main Neil McIsaac & Son dairy encompasses 250 acres and has over 300 cows and 5,000 chickens, but they also have several other properties nearby for grazing and growing feed, which totals over 700 acres.

Growing up on the dairy, Neil was always a hard worker and he always loved the hay trucks that would come into the dairy. Neil’s dad (Neil II) was never really into trucks, but because they were a necessity on the dairy, he had some. At a very early age, Neil started driving trucks on the dairy, hauling liquid manure in an International with a gas engine and two sticks. When he turned 16, he began driving manure and silage trucks around town, and doing some custom harvesting. On a trip with his dad to Oregon, Neil saw his first narrow-nose Peterbilt and he fell in love. He said, “One day I want to have one of those!”

After graduating from high school, he tried going to the local junior college, but that only lasted about eight months. Not long after leaving school, he got the opportunity to go work for Bill Chisholm, a hay-hauler from Petaluma. Not having his license yet, Neil spent some time loading and unloading trucks with the hay squeeze and then, at 19 years old, got his CDL. Bill put him in a truck immediately, and sent him out to run with one of his veteran drivers. These two ran together for a few years, and Neil loved it.

In 1995, Bill bought two brand new glider trucks – 1995 Freightliner COEs – and dropped a 3406C Cat in each one. Neil got to drive one of these trucks and put 150,000 miles on it in less than two years (that is a lot for a hay truck that did not travel very far from home). But, life on the road was beginning to take its toll, so when Neil got the opportunity to come home and start running the dairy, he took it. He also wanted to start a family. Getting together with one of his sister’s friends, she and Neil were married in May of 1998, and two years later, Neil’s first son, Harrison (now 15), was born.

Several years before all this, in 1991, Neil’s dad bought their first Peterbilt – a 1975 model 359 with a 335 Cummins and a 9-speed. They put a tank on this truck and used it to haul liquid manure on the dairy. Then, in 1997, Neil bought his first truck – a 1970 Pete 359A wide hood dump truck with a Detroit 8V92, and started using it to haul dry manure, rock, and whatever else needed to be moved on the ranch. Around 1999, Neil’s dad bought a 2-axle 1977 Pete 359 with a Big Cam III Cummins 400 and a 13-speed. This truck (#3) is a special truck because it was originally ordered by Neil’s grandfather for a local creamery he worked with. When the creamery decided to get rid of it, Neil’s dad, wanting to keep it in the family, bought it.

By this time (around 2000), the dairy was dialed-in and running well, so Neil’s dad said that if he wanted to go back to hauling hay, he could use the ’77 Pete. Jumping at the chance, Neil bought a set of used Tuff Boy hay trailers and went back to hay trucking. But, not long after that, someone quit at the dairy and Neil had to go back to run it. That was also a very dry year, so Neil had to start hauling water, which they bought from the City of Petaluma, into the dairy – at the rate of three double tanker loads a day! Needless to say, the hay-hauling trips came to an end – again. A few years later, unfortunately, Neil’s marriage came to an end, as well.

After his divorce in 2003, Neil was all about work. Growing the dairy to 450 cows and doing some hay-hauling on the side, a local cement company decided to sell some of their older equipment so Neil decided to build up their “farm fleet” a bit. Over the next year or so, Neil bought four ready-mix trucks – all of them were Peterbilt 348s with Cat 3306 motors – one was a 1984 with dual sticks (he stripped off the ready-mix body, scrapped it, and put a tank on it); the next one was another 1984 but this one had a 7-speed (he mounted a spreader box on this one); the third one was a 1985 with dual sticks (he put a tank on this one, too); and then the last one was another 1985, which he just parted out and then cut up the rest for scrap.

Later, Neil added more trucks to their fleet when he bought three Internationals – an ’82, ’84 and ’91 – all with DT466 motors. Two of these were made into feed wagons and the third is a sand spreader. Most of these trucks work every day on the dairy, but some of them are only used in the summer.

Back in 1993, when Neil was still hauling hay for Bill Chisholm, he spotted a worn-out narrow-nose Pete sitting in one of his neighbors’ fields. Calling them up and asking them if they wanted to sell it, their answer was no – they had plans to make a spreader truck out of it. Well, that truck sat there, in the field, for ten more years. Neil called them again, but their answer was still no. Shortly after that, they pulled it out of the field and put it next to their barn. Neil thought they were finally going to do something with it, but they did not – it sat next to that barn for another five years.

Finally, Neil called, made them an offer, and they said, “Come and get it.” This was in 2008. So, after 15 years of trying, Neil finally had his dream truck – a 1969 Peterbilt 358A with a tilt hood (he has never been a fan of butterfly hoods). But this truck was rough.

Neil had never tore apart and completely rebuilt a truck, but he started doing it anyway. Before long, the truck was reduced to frame rails and several piles around his shop! Fitted with a 318 Detroit motor, two sticks, and a Hendrickson suspension, Neil took all of that stuff off, including the rear ends, and scrapped it. Taking it down to bare frame rails, he realized that those were in bad shape, too. Using the rails out of a 1965 Pete he bought for parts, he took them to a local welding shop where they cut off and replaced the rear sections, sleeved them, and filled all of the holes. Starting fresh with clean rails, which he painted black in his shop, every hole (except the cab mount holes) would have to be re-drilled.

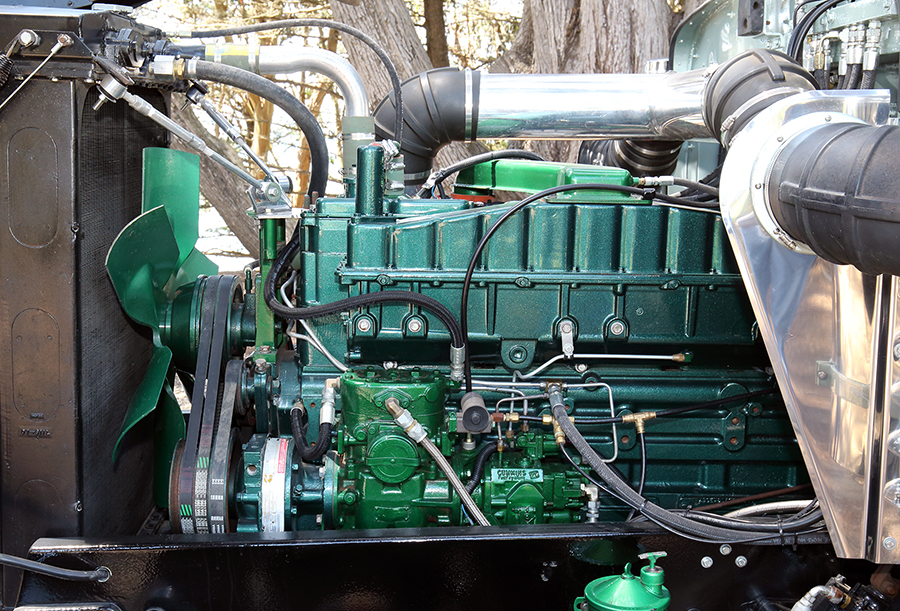

After drilling all the holes and mounting the new cross-members, Neil rolled the new Eaton DS404 rear ends under the chassis and bolted them on. With the original axle still intact up front, he now had a rolling chassis (he did take 9 of the 12 leaf springs out, though, and then installed an air-ride kit from 4 State Trucks). The Cummins Big Cam III 400 he had bought was sitting there, ready to be installed, but Neil wanted to have it painted first. Originally, the truck was going to be forest green and a grass green color, like most of Neil’s other trucks, so those are the colors that the local painter used (later, the color scheme was changed a bit, so the motor does not match exactly right now – but it will).

Finding parts for this truck was not easy. Wanting a Pete Low-Air suspension, Neil had to get it from Rocky Mountain Truck Parts in Ogden, Utah (this is also where he got the engine and 13-speed transmission). After the engine came back from the painter, Neil spruced it up a bit more, made some custom motor mounts, and then put it, along with the transmission and rear suspension, in the truck. Now, it was time to see how it would look with the cab on it, but he quickly realized that the new engine was a lot bigger and that the flat firewall would not work. After locating a firewall with a cutout at G & O Truck Parts in Jackson, California (a boneyard out in the middle of nowhere), Neil was back in business – and the cab fit perfect. But, now is when the problems really began.

The hood got damaged when they pulled the rig out of the field, so Neil sent it to Courtland Truck Works to be rebuilt. When it came back, he sent the cab and hood to the same local painter that did his engine (and every truck he had ever had painted) to be sprayed, but not long after that, the guy skipped town, and took Neil’s money with him. After getting his parts back, Neil sent them to Bill Rocha in Oakdale, California, but Bill did not like the colors that Neil had chosen. Eventually, he convinced Neil to change the grass green to metallic mint green, to go better with the other color, which is a dark forest green. Neil agreed, and Bill started painting.

After the hood was sprayed, Bill noticed that it wasn’t right, so Neil had Bill rebuild the hood again. Bill also did extensive repairs on the cab, painted it, and then added 11 cab lights. Taking them back to his shop, Neil was excited to start seeing everything come together. A few days later, Neil’s mechanic and friend, Danny Norwood, came over to help. After getting the cab set with no problems, they put the hood on, but it didn’t close properly. As hard as they tried to make it work, it just wouldn’t. They headed back to Bill’s place only to find out that he had retired and sold his business! Thankfully, the new guy, John Chamorro of Colorworx Paint & Fab, was able to fix the hood and get it right – the third time is always a charm!

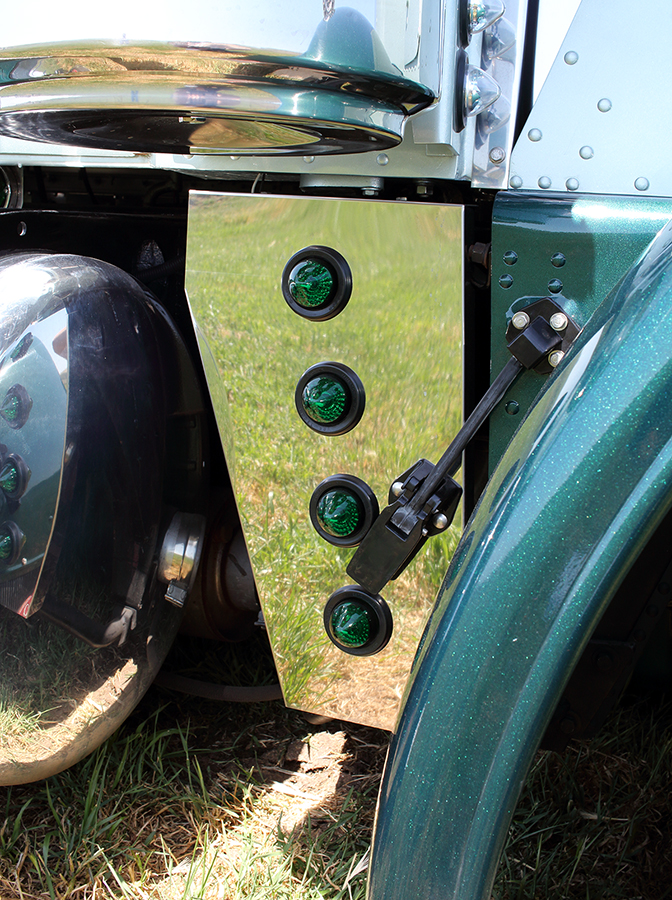

Finally, it was time to start adding the bling. Getting many of the accessories from our friends at 4 State Trucks in Joplin, Missouri, Neil installed 8-inch Dynaflex pipes with “Chino” tips and Pickett elbows, a new visor, a 22-inch American Eagle bumper, new air cleaners, new headlights, Hogebuilt stainless quarter fenders and all LED lights. To accommodate the 50-gallon fuel tanks he mounted on each side, Neil moved all of his batteries and air tanks to the inside of his frame rails, and then added stainless tool boxes on both sides underneath the bed, which Neil bought as a kit and then fabricated himself (John at Colorworx painted it). Neil also bought and installed an electric windshield wiper conversion kit, stainless rear light bars, a billet grill, and a custom headache rack, complete with a stainless panel featuring a cutout of Neil’s ranch brand.

Moving inside the cab, a lot was done in there, too. All of the dash pieces were painted green, new Isspro gauges were installed, a Colorado Custom steering wheel was added, as well as a custom shifter, made by Neil and Danny Norwood, using hollow tubing to hide all of the lines inside. The interior also features Bostrom Low-Ride seats, custom gray door panels with Neil’s ranch brand embroidered on them, along with custom mirrored-stainless window sill trim pieces, an overhead console for the stereo and speakers, and a partially-carpeted and painted aluminum floor. Hendrickson’s Upholstery in Petaluma did much of the interior work, including the vinyl-covered firewall and headliner.

The mostly-completed truck made its debut at the Peterbilt show in Stockton, California in October of 2014, where it was a big hit. Keep in mind, while all of this building was happening, Neil was also running the dairy, which recently switched over to 100% organic to be more profitable, and, in 2010 he got married to the love of his life, Jessica. Later that year, they had twin boys, Hayden and Hunter (4), and last year, their daughter Hettie (1) was born. Neil is a busy boy – it’s a wonder this project did not take even longer! All of the kids have grown up on the dairy, and they love riding around in the trucks – even if it’s just around the dairy.

Neil wanted to thank his wife and kids for all of their love and support (this build was truly a family affair), along with his ranch mechanic, Danny Norwood, who has been working on all of Neil’s equipment for the past 30 years, and, of course, Neil’s parents, who still live on the dairy right next door to Neil, and help run things.

Already thinking about his next project, Neil would love to build another tilt-hood ‘69 just like the hay truck, but make it a long and low tractor and hook it to a belt trailer for the ranch. But, for now, he will just savor in the fact that he was able to tear this truck apart and successfully put it all back together – which was not something that he was entirely sure he could do.

And, Neil not only put the old truck back together right, but he made his boyhood dreams come true by creating the hot rod hay sleigh he has always wanted. Not bad for a simple dairy farmer with no time or experience! It just goes to prove that if you have patience and never give up, you can do anything you set your mind to.