Striving to be the best is never easy, but some companies have made it their mission. Now entering their 20th year, RoadWorks Manufacturing, Inc. has worked diligently and persistently to become the world’s best manufacturer of innovative aftermarket accessories for class eight trucks. Focused on making quality American-made products and always striving to innovate with new and cutting-edge accessories, RoadWorks has become a shining example (literally) of what it means to build a successful outfit from the ground up, proving that the American Dream is alive and well.

Started in 1994 with just one new machine and a lot of used equipment, RoadWorks’ early products were mostly light panels and mudflap weights. Today, with thousands of items, RoadWorks has become one of the top truck accessories manufacturers in the country. “It’s a never-ending and important challenge to keep our product current with all the ways that trucks have become so specialized. We are grateful to have the technology that makes it possible to communicate with all our customers concerning their individual truck and produce exactly what meets that truck’s specifications and the look that certain individual driver desires,” says Susan Linson, owner of RoadWorks.

Susan first became acquainted with the scope and importance of the trucking industry when she worked at her local International truck dealer back in the 1970s. “I came to appreciate the good folks who transport all of the products we use every day across our country, and upon whom our country’s strength depends. Owning this company has allowed me to continue to serve and participate in this industry for which I have so much respect. It is a personal passion of mine to manufacture in the United States at a time when so much manufacturing has been moved offshore. Manufacturing here, in the USA, is the key to our flexibility and innovation. It fulfills my desire to do my part to keep America strong,” says Susan.

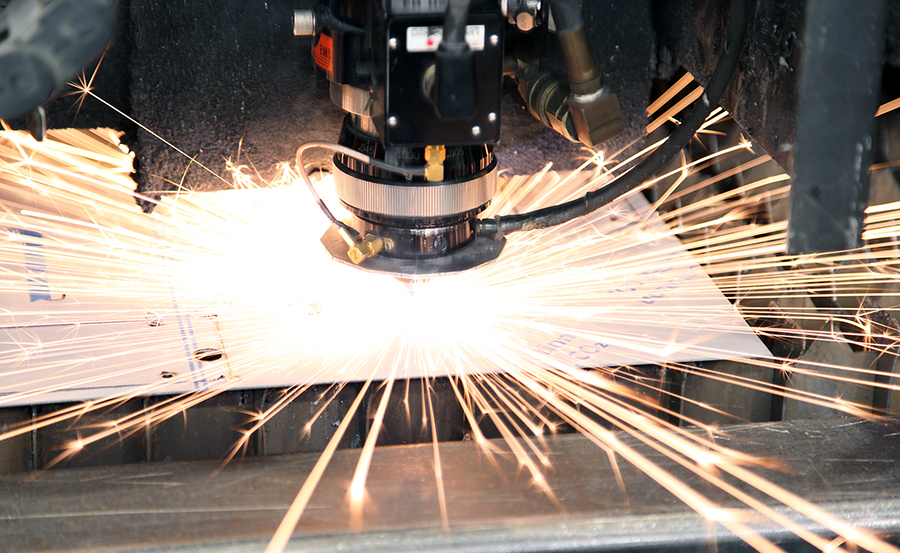

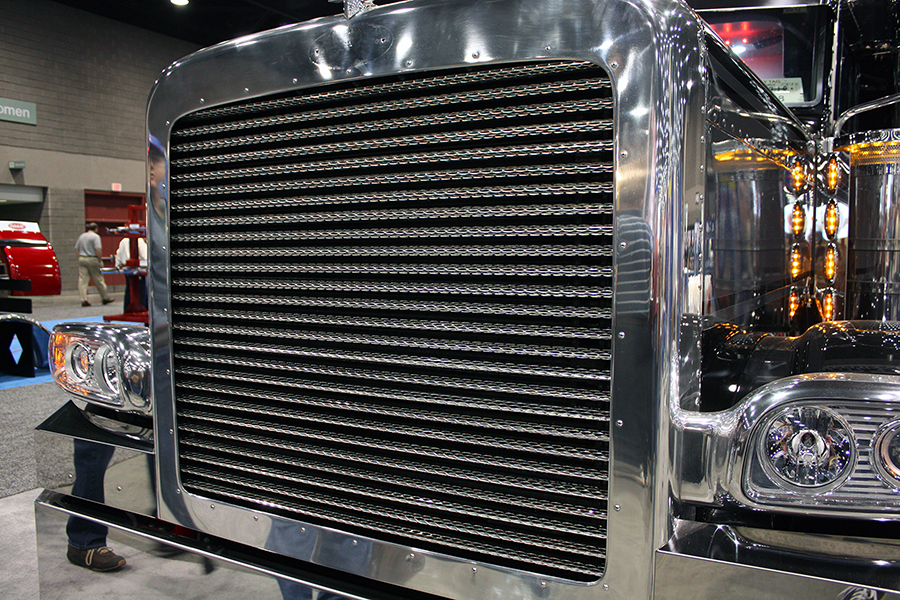

Offering products in both 430 and 304 stainless steel in gauges from 22 to 11, RoadWorks uses nothing but the best raw materials, produced in mills in the USA, to manufacture their numerous products – and, all of their polishing is done here, too. Located in Lafayette, Indiana, RoadWorks built its current, state-of-the-art manufacturing facility and moved production there in June of 2006. From their modest beginning in 1994, RoadWorks is now equipped with Fiber Lasers, multiple press breaks, rollers and punches. This new equipment has allowed RoadWorks to produce a much wider range of products including stainless steel bumpers, visors, grills, rear light bars, deck plates, and custom orders, as well. And, taking their stance on using (and producing) American-made products to an even higher level, most of the equipment in their factory was also made in the USA!

When RoadWorks built their current facility, they devoted an entire area solely to new product development. In this area, the newest truck models are brought in, built and photographed. “The products and images produced in the development area of our plant are then included in our now over 300-page catalog, which we update every year. We invite everyone to visit our site (www.roadworksmfg.com) and click on the catalog request button to get a catalog mailed to them directly from the factory at no charge,” says Mike Horan, head of RoadWorks product development team. Mike, who worked at a chrome shop and was a customer for many years before becoming part of the RoadWorks team in 2000, has become a good friend to all of us here at 10-4 Magazine. Over the years, we have had a lot of fun with Mike and his crew at the shows we attend across the country.

As part of their extensive product development and marketing program, RoadWorks builds a cool “show truck” featuring their latest products each and every year – they have been doing this for the past eleven years. This truck, which they drive to and from each show, is always a sweet ride. For the last eight years, these trucks have been spec’d by our friend Clint Moore at Kansas City Peterbilt. Each year, Clint orders the new truck as well as selling the previous year’s rig. After Clint and his team take delivery of the truck they do any needed paint work, hang the Fibertech fenders, install a set of Lincoln Chrome stacks and elbows, and swap the factory seats with Seats Inc. Legacy LO series leather seats. Once Clint has done his part, the truck is taken to its new home at the RoadWorks factory in Indiana where they outfit it with all of the products they want to highlight that year (a few of their past show trucks can be seen here in the pictures on these pages).

Looking to always grow and expand their offerings, the RoadWorks product development team launched a new line of detail products in 2011 called Mojo Detail Products. The line currently has three products – Mojo Metal Polish and Sealant, Mojo Paint Protectant, and Mojo Metal Polish & Sealant single-use wipes. All three of these products are easy to use and have a pleasant scent. Look for them at your favorite RoadWorks dealer. The company also plans to add additional products to the Mojo line in the near future, so look for those soon.

With a dealer network that now spans the globe, RoadWorks’ main goal continues to be their slogan, which asks the question, “Do heads turn when you drive by?” With quality materials and a commitment to excellence, innovative ideas and high-tech equipment, the truck accessories produced by the folks at RoadWorks are second to none. And with a caring and creative staff of over 30 employees, which includes a hands-on owner and a hard-working and committed product development leader, RoadWorks is poised to shine even more in the coming years. We are proud to not only have RoadWorks Manufacturing in the 10-4 family of advertisers, but to also call them friends! To learn more about their quality, American-made, stainless steel truck accessories and detail products visit them at www.roadworksmfg.com or call them at 1-800-448-8741.