In the world of transportation, the Class A diesel industry stands as a vital artery, facilitating the movement of goods across our country. However, there lies a crucial and often overlooked aspect: prechecks. These routine inspections, conducted before hitting the road, are essential in ensuring the safety of drivers and fellow road users. Neglecting or performing these prechecks incorrectly can have dire consequences, posing significant risks to everyone on the road.

Prechecks are not just a formality but a cornerstone of safety in the Class A diesel industry. Before going on a journey, drivers and operators should meticulously inspect their vehicles for any signs of wear, malfunction, or potential hazards. To ensure the optimal performance of your truck, every component should be scrutinized, from brakes and tires to lights and fluid levels. These prechecks serve as the first line of defense against mechanical failures, which can lead to devastating accidents on the road.

One of the primary reasons prechecks are so important is their role in preventing accidents caused by equipment failure. Class A diesel vehicles are machines capable of inflicting immense damage in the event of a malfunction. A simple oversight, such as worn brake pads or inadequate tire pressure, can escalate into a catastrophic failure and potentially a collision. By conducting thorough prechecks, drivers can identify and fix potential issues before they compromise safety, thereby protecting themselves and other drivers, pedestrians, and cyclists sharing the road with them.

Proper prechecks also contribute significantly to environmental sustainability. Diesel engines, while efficient, emit pollutants that can harm air quality and contribute to environmental degradation. Ensuring that emission control systems are functioning correctly, prechecks help minimize harmful exhaust emissions, thereby mitigating the possible environmental impact of diesel vehicles. This commitment to being environmentally responsible benefits present-day communities and preserves natural resources for future generations. This is one of the main reasons our Max Mileage Fuel Borne Catalyst exists.

The importance of prechecks extends beyond individual safety and can have other implications. Accidents involving Class A diesel vehicles can result in substantial economic losses, including property damage, medical expenses, and productivity downturns. By diligently performing prechecks, drivers and operators reduce the risk of accidents, thereby minimizing the economic burden on individuals, businesses, and governments. A culture of safety and responsibility promoted through prechecks also contributes to a more resilient and sustainable transportation infrastructure.

Overlooking prechecks undermines both the credibility and professionalism of the Class A diesel industry. As stakeholders in a critical transportation sector, drivers and operators are responsible for upholding safety standards and best practices. Failure to adhere to precheck protocols not only jeopardizes individual safety but also tarnishes the industry’s reputation. Instances of accidents resulting from negligent prechecks can erode public trust and confidence in the reliability and safety of diesel trucks, and lead to more scrutiny.

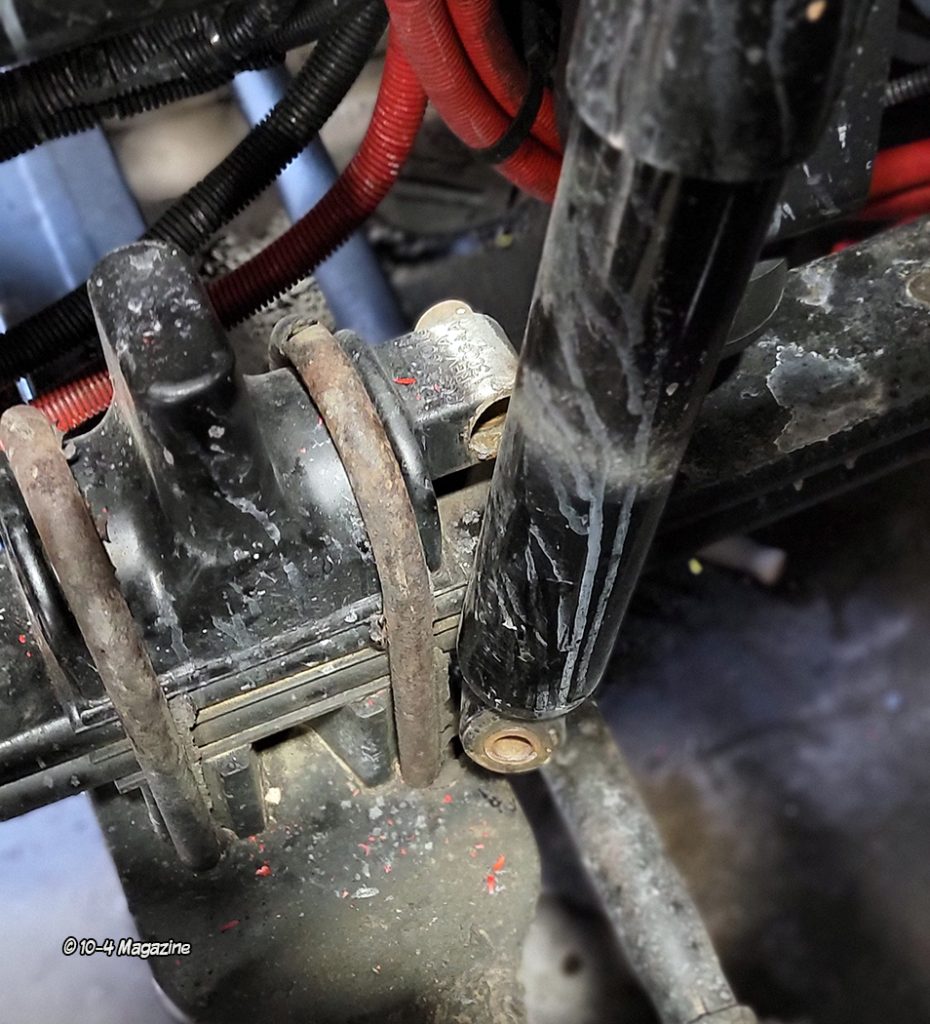

Just recently, a routine inspection at our shop revealed a shock absorber extremely close to detaching from the front left steer of a truck. The gravity of the situation cannot be understated, as this component was moments away from dislodging itself and becoming hazardous. While the scenario may seem innocuous when described in casual terms, the implications of such negligence are grave, especially when 80,000-pound vehicles are hurtling down the road at speeds upwards of 70 miles per hour.

The potential consequences of this oversight can be dire. What might have appeared as a mere inconvenience – a loose shock absorber – possesses the capacity to transform into a 15-pound projectile capable of inflicting severe harm on other road users. While the idea of a component detaching itself from a vehicle may elicit a chuckle from some in less severe circumstances, the reality is starkly different when considering the speed and force of impact involved in highway travel.

These near-miss incidents underscore the critical importance of adhering to precheck protocols within the Class A diesel industry. Loose bolts, worn brake pads, and dangling shock absorbers are not mere inconveniences but glaring indicators of potential hazards that demand immediate attention. Every overlooked detail in prechecks represents a potential risk to road safety for the driver and all the other individuals sharing the road with him or her.

Neglecting prechecks has repercussions beyond the immediate incident. When safety protocols are disregarded, the integrity and overall reputation of the Class A diesel industry are at stake. Again, negligence erodes public trust and invites scrutiny and other legal ramifications, imposing financial and operational burdens on businesses and drivers alike. So, do those prechecks every day, and do them right! Thanks to Jordan Greathouse at Pittsburgh Power for providing this article. Feel free to drop by our shop in Saxonburg, PA during regular business hours, visit www.pittsburghpower.com anytime, or call (724) 360-4080 to learn more about our services.