November 2008 - Performance Zone

MOTOR MADNESS!

By Performance Specialist Bruce C. Mallinson

There is confusion in the industry when it comes to engines, and when it comes to engines, many people are confused. Is that confusing? When I open the hood of a newer car and can’t see the spark plugs or plug wires, even I am a little confused. Engines can be very complicated today, including the electronic diesel engines in our semi trucks. The first time I looked under the hood of a new Peterbilt with an Acert Cat and a diesel particulate filter (DPF) I thought, “Holy hell, the devil is upon us now!”

So how do we at Pittsburgh Power learn about new technology and what’s going on under your hoods? We read, study, take it one sensor at a time (sometimes one wire at a time) and figure out what it does. Once we find that one wire that allows us to add fuel, there is a Pittsburgh Power Computer coming for that engine. But that is just where we start – with a wiring diagram and one wire. But it always seems that once we get the engine purring like a kitten at idle and roaring like a lion at full throttle, the OEM’s go and change something in the ECM, un-doing much of what we just did. Then it’s back to the dyno with another truck to figure that one out.

These constant changes are one of the reasons it’s taking us so long to get the ISX engine figured out. We need your patience with this engine. We currently have a 2009 Peterbilt with an ISX and a DPF out on the road for testing and it is doing fine, however we need more test trucks. If you drive through Indianapolis on a regular basis and have an ISX Cummins-powered truck, we need your assistance. Our engineers will arrange to meet with you and then install a Pittsburgh Power computer, take some readings, and then report back to us as to how it is running. Once all of the final calculations are figured, you will get the computer at half price (this is how we pay people for their time).

These constant changes are one of the reasons it’s taking us so long to get the ISX engine figured out. We need your patience with this engine. We currently have a 2009 Peterbilt with an ISX and a DPF out on the road for testing and it is doing fine, however we need more test trucks. If you drive through Indianapolis on a regular basis and have an ISX Cummins-powered truck, we need your assistance. Our engineers will arrange to meet with you and then install a Pittsburgh Power computer, take some readings, and then report back to us as to how it is running. Once all of the final calculations are figured, you will get the computer at half price (this is how we pay people for their time).

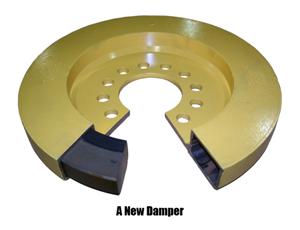

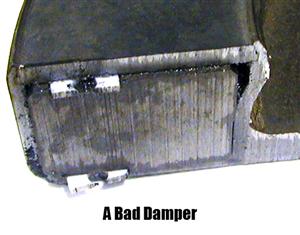

There is also confusion about dampers and balancers. The torsional damper, which is the large round item on the front of the crankshaft, spins with the crankshaft. Inside the outer housing you can see is a large steel ring. This ring rides on Teflon and floats in silicone. After 500,000 miles or less the Teflon starts to disintegrate and pollutes the silicone, causing the silicone to harden. Once the silicone hardens the damper seizes up and is useless.

Now, for all of you service managers and mechanics out there in the dealerships throughout this country that won’t take the time to read, listen and figure out what is causing all of the problems with some of the trucks you are working on, I’ll tell you, again – it is the crankshaft damper. It’s you guys who keep telling my owner operator friends that the damper never wears out. That is a bunch of BS! It is time you get your head out of the clouds and help these people.

Vibration breaks things. I just recently heard from an owner operator via e-mail. He told me that his truck only had 240,000 miles on it when the springs broke out of the center of the clutch. The service manager at the truck dealership told him he doesn’t know how to drive. This owner operator was raised on a farm and drove his first vehicle at the tender age of seven years old. He has probably been driving longer than this particular service manager has been alive. Gentleman, the crankshaft damper on this engine is shot – just replace it and the problem is gone.

While we are on the subject of dampers, we need to clarify one more thing – the crankshaft damper is not a balancer. For years we called them balancers on the front of the small and big block Chevrolets we raced, but that term is not correct. The correct name is a torsional damper. When the injector fires and slams the piston to the bottom of the liner, the connecting rod tries to twist the crankshaft in two. If your engine is running at 1,400 RPM, the injector fires 700 times every minute. So, every minute your engine is running, your crankshaft is trying to be broken in half 700 times (at idle it is only 350 times per minute). By the way, the lower you pull the RPM’s down when you’re pulling a hill, the harder you’re bending your crankshaft.

While we are on the subject of dampers, we need to clarify one more thing – the crankshaft damper is not a balancer. For years we called them balancers on the front of the small and big block Chevrolets we raced, but that term is not correct. The correct name is a torsional damper. When the injector fires and slams the piston to the bottom of the liner, the connecting rod tries to twist the crankshaft in two. If your engine is running at 1,400 RPM, the injector fires 700 times every minute. So, every minute your engine is running, your crankshaft is trying to be broken in half 700 times (at idle it is only 350 times per minute). By the way, the lower you pull the RPM’s down when you’re pulling a hill, the harder you’re bending your crankshaft.

Yes, your driving habits can break your crankshaft – and it is only $25,000 to replace it and rebuild the engine. But that is okay – the truck salesman and the service manager told you to lug your engine down to 1,100 or 1,200 RPM when pulling a hill, citing, “It will save you fuel.” This is incorrect. How far you push on the throttle is what saves you fuel, not lower RPM. If it takes fuel to make turbo boost, and lower RPM’s require more boost to pull a grade while higher RPM’s (such as 1,400 to 1,800) require less boost to pull the same grade, which one is saving you fuel and your engine? Think about that! One more thing, the higher RPM’s while pulling will result in lower EGT’s (exhaust gas temperatures), which will help to protect your turbo and exhaust manifold from being burned out. Do you think that will save you money?

Have you ever heard the term nomenclature? I once had an instructor at fuel injection school in Ft. Worth, Texas who was an ex-Marine. Even though he was younger than me, he was really tough on me. He tried to beat it into my head that I couldn’t build performance diesel engines. I knew better, so I just put up with him for one long week. But the one thing that this man taught me about was nomenclature – calling a part by the right name. Don’t call a fulcrum in an injection pump a lever or a thingamajig – call the part by the proper and correct name. So, please, call a crankshaft damper a damper and not a balancer.

And when your damper has around 500,000 miles on it, please call us and purchase a new damper to save your crankshaft. I would recommend that you do not buy a damper from Caterpillar or Cummins. Caterpillar walked away from the original manufacturer of their dampers here in the good old USA to have theirs made in India, while Cummins went to China – all for cheapness! Ours are still made in the USA by the original inventors of the liquid-filled crankshaft dampers. We appreciate your business and will keep your well-spent money right here in our own country!

And when your damper has around 500,000 miles on it, please call us and purchase a new damper to save your crankshaft. I would recommend that you do not buy a damper from Caterpillar or Cummins. Caterpillar walked away from the original manufacturer of their dampers here in the good old USA to have theirs made in India, while Cummins went to China – all for cheapness! Ours are still made in the USA by the original inventors of the liquid-filled crankshaft dampers. We appreciate your business and will keep your well-spent money right here in our own country!

Now that we all know it’s a damper and not a balancer, it only makes sense to also realize that the damper does not balance the engine. Being that I’m always looking for ways to improve diesel engines and the trucks they reside in, I tried the Centramatics on my 1989 Dodge Cummins pickup and liked them (until the balance ring fell off of the backing plate). Then, on my newer 1995 Dodge Cummins pickup, I discovered the steel chrome factory wheels were .080 out of round. And we think the OEM’s make everything perfect! How can their engineers ever be wrong? I loved the truck but hated the ride. Luckily, I knew Chris Gamble, owner of Balance Masters, from working many truck and RV shows with him. I asked Chris if the mercury-filled Balance Masters would compensate for the .080 out of round wheels on my Dodge. He said, “Let’s give it a try!” They made a remarkable difference. I also tried some of Chris’ products on my Harley Davidson, installing them on the engine and transmission, and the bike ran noticeably smoother.

At age 47 I just had to drive a semi truck and wanted to spend time out west so I purchased a 1989 T-600 Kenworth, reworked this ex-fleet truck, hooked a fifth wheel RV behind her and headed west. Arizona was my destination – the Quartzsite Arizona RV Show. Jon Anderson and I built this KW and installed nine air bags (I have air bags on everything, and she floats down the road like a Cadillac). While working a show with Chris of Balance Masters, I asked him if I made the mold would he make me a mercury-filled balancer for the front of the NTC Cummins in my T-600. He asked for the particulars of my engine, I made the mold, he built the balancer and then I installed it behind a silicone-filled damper and went for a ride. Since I did not drive this truck every day and it already rode very smooth, it was hard to tell if it made a difference, but it felt like the smoothness of the engine had improved. In fact, I found myself shifting 200 RPM higher than usual, so I had to start looking at the tachometer to figure out when to shift.

After the first trip, I got used to the smoother-running engine and no longer had to watch the tachometer. So I built two more mercury-filled balancers – one for my brother Brian’s 444 Cummins and one for Calvin Catch who had a 1997 Pete with a 5 EK Cat with all of our performance items installed. Both men noticed that their engines and trucks were smoother with the addition of the balancer. Keep in mind, the mercury-filled balancer balances the engine and the silicone-filled damper takes the torsional twisting out of the crankshaft. These two items are both mounted on the front of the engine, however they both do different things. Do you need both? Not really, but you need the damper. If you want to improve the smoothness of your engine and truck and eliminate vibrations, then you’ll also want the mercury-filled balancer. And by eliminating vibrations, your body won’t be as tired at the end of a day of driving. Vibrations wear out your body and your truck.

After the first trip, I got used to the smoother-running engine and no longer had to watch the tachometer. So I built two more mercury-filled balancers – one for my brother Brian’s 444 Cummins and one for Calvin Catch who had a 1997 Pete with a 5 EK Cat with all of our performance items installed. Both men noticed that their engines and trucks were smoother with the addition of the balancer. Keep in mind, the mercury-filled balancer balances the engine and the silicone-filled damper takes the torsional twisting out of the crankshaft. These two items are both mounted on the front of the engine, however they both do different things. Do you need both? Not really, but you need the damper. If you want to improve the smoothness of your engine and truck and eliminate vibrations, then you’ll also want the mercury-filled balancer. And by eliminating vibrations, your body won’t be as tired at the end of a day of driving. Vibrations wear out your body and your truck.

I had the pleasure of working with Kevin Rutherford on XM 171 on Sunday the 5th and 12th of October. We talked a lot about what we are talking about here – dampers and balancers. In fact, I wrote this article because of the high amount of phone calls we received from owner operators that did not know about how dampers wear out or the difference between a damper and a balancer. I hope it has been a helpful article. If you have any performance-related comments or questions, please feel free to contact me via e-mail at bruce@pittsburghpower.com or through Pittsburgh Power Inc. in Saxonburg, PA at (724) 360-4080.