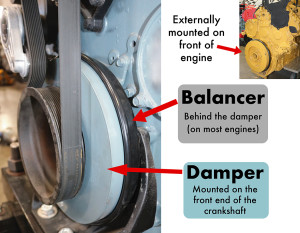

Many owner operators ask us about the difference between a damper and balancer, wondering if they need one or both, and what is the purpose of each item. Let’s start with the Torsional Viscous Damper and why you should replace it every half a million miles. Every truck engine is equipped with a torsional damper from new. It’s a heavy circular object that sits on the end of the crankshaft externally on the engine. Its job is to dampen vibrations coming from the crankshaft. This is an important job because your crankshaft deals with a lot of vibrations that can weaken the metal and eventually lead to failure.

Many owner operators ask us about the difference between a damper and balancer, wondering if they need one or both, and what is the purpose of each item. Let’s start with the Torsional Viscous Damper and why you should replace it every half a million miles. Every truck engine is equipped with a torsional damper from new. It’s a heavy circular object that sits on the end of the crankshaft externally on the engine. Its job is to dampen vibrations coming from the crankshaft. This is an important job because your crankshaft deals with a lot of vibrations that can weaken the metal and eventually lead to failure.

Torsional dampers are made from steel and filled with silicone. Over time, that silicone hardens and becomes ineffective. This is why all manufacturers recommend replacing the damper every 500,000 miles. If not replaced, not only will you feel the vibrations through the cab, but your engine and your back will be taking a beating. It’s a small investment compared to having to replace a crankshaft, or even the whole block. Harmonic balancers are similar in function but different. They are basically a smaller damper for your car’s gasoline engine, use rubber instead of silicone, and often double as a pulley.

The crankshaft balancer is an exclusive product from Pittsburgh Power. The balancer is a thin piece of metal with a mercury-filled ring along the outside. It can be mounted on the torsional damper for an even smoother running engine. The mercury will move to the lighter side, correcting any imbalances in the rotating mass. If one of your connecting rods is a few ounces heavier (or lighter), it’s going to throw off the balance of the whole engine. As a result, you will have increased vibrations. The damper will help reduce those vibrations, but it can’t correct an imbalance like a balancer can. Balancers are optional equipment, but they have a lifetime warranty and will increase the longevity of your engine. We recommend installing both a damper and a balancer, but, in the very least, you should have your damper replaced every half a million miles.

If your truck has a common-rail fuel system, listen up – you may want to learn how to perform a High-Pressure Fuel Pump Performance Test. On most common-rail fuel systems, the high-pressure fuel pump is creating over 29,000 psi of pressure! Not surprising, it’s a common point of failure in the fuel system. Sometimes, the internal parts of these high-pressure fuel pumps can break apart, but other times there may be a subtle issue creating too much or too little pressure. The procedure is slightly different for every engine, so please look up the manufacturers’ instructions before you begin the test.

If your truck has a common-rail fuel system, listen up – you may want to learn how to perform a High-Pressure Fuel Pump Performance Test. On most common-rail fuel systems, the high-pressure fuel pump is creating over 29,000 psi of pressure! Not surprising, it’s a common point of failure in the fuel system. Sometimes, the internal parts of these high-pressure fuel pumps can break apart, but other times there may be a subtle issue creating too much or too little pressure. The procedure is slightly different for every engine, so please look up the manufacturers’ instructions before you begin the test.

Basically, the test consists of the following: First, relieve pressure from the system by loosening the nut on the pump-to-rail line. Second, tighten it back up. Third, block off five injectors at the fuel rail, leaving the most accessible injector unblocked (you’re going to need a high-pressure fuel pump service tool to plug into that 6th injector line). Clear any debris or residual fuel from the area before installing the tool. Fourth, crank the engine for 15 seconds at a time, being careful not to crank longer than that, as you could burn out the starter motor. Fifth, disconnect the fuel pump actuator and injector pass through from the electrical harness. Sixth, connect a drain line from the fuel pump service tool to a graduated beaker (yes, like the ones you used in your high school chemistry class). Crank the engine to purge any air from the system. Finally, crank in two 15-second intervals and measure how much fuel you have in your beaker.

Too little fuel can mean weak pressure, and too much fuel could mean the pressure is too high. The volume of fuel will vary for different engines and RPM speeds, so refer to your manufacturers’ guide for this procedure. You’ll want to be within a specific range to make sure the high-pressure fuel pump is working properly. If this sounds too complicated for you to do yourself at home, bring your truck to us and we will perform the test for you in our shop!

No plans for Saturday, October 3rd? Come to our truck show! Pittsburgh Power and Long Haul Custom Detailing will be hosting the first annual Victory Road Truck Show. It will be located in our business park in Saxonburg, PA. There will be a Show N’ Shine, live dyno runs on our chassis dyno, food trucks, kid’s activities, and much more. Plus, there will be raffle prizes and giveaways. Dyno runs will be discounted to $275 and ECM tunes will be discounted 25%. We’ll have limited space, so please call us if you’d like a dyno run or ECM tune that day. All entry fees will be donated to charity, and the raffles will benefit local volunteer fire departments. For more details, call us at (724) 360-4080 or visit www.pittsburghpower.com.

No plans for Saturday, October 3rd? Come to our truck show! Pittsburgh Power and Long Haul Custom Detailing will be hosting the first annual Victory Road Truck Show. It will be located in our business park in Saxonburg, PA. There will be a Show N’ Shine, live dyno runs on our chassis dyno, food trucks, kid’s activities, and much more. Plus, there will be raffle prizes and giveaways. Dyno runs will be discounted to $275 and ECM tunes will be discounted 25%. We’ll have limited space, so please call us if you’d like a dyno run or ECM tune that day. All entry fees will be donated to charity, and the raffles will benefit local volunteer fire departments. For more details, call us at (724) 360-4080 or visit www.pittsburghpower.com.