Many people are looking to rebuild their older 60 Series Detroit or 3406 Caterpillar engines for either new glider kits or their older rigs. If that is you, then this article will be of utmost help. Many of these engines, which are 18 to 23 years old, could have in excess of two million miles, which probably means that it’s time for that older engine block to be reconditioned at a reliable machine shop that is capable of making lower counter bore repair sleeves. The lower counter bore repair sleeves for the Big Cam Cummins, as well as the 3406 and C-15 series of Cat engines, are available from the engine manufacturer.

Many people are looking to rebuild their older 60 Series Detroit or 3406 Caterpillar engines for either new glider kits or their older rigs. If that is you, then this article will be of utmost help. Many of these engines, which are 18 to 23 years old, could have in excess of two million miles, which probably means that it’s time for that older engine block to be reconditioned at a reliable machine shop that is capable of making lower counter bore repair sleeves. The lower counter bore repair sleeves for the Big Cam Cummins, as well as the 3406 and C-15 series of Cat engines, are available from the engine manufacturer.

The lower counter bore is the section of the block where the packing and liner O-rings seal the cylinder liner to the engine block to keep the antifreeze from entering the oil pan. This is a very critical part of engine rebuilding, but it is often overlooked by mechanics performing an in-chassis rebuild. The 60 Series Detroit engine has two lower counter bores per cylinder, with a coolant passage between the two sealing areas. Detroit does not make the repair sleeve for this fix – it is my understanding that they just scrap the engine block. The machine shop that Pittsburgh Power has been working with for the past 40 years can make and install the two repair sleeves needed to salvage the engine block.

It’s never welcomed news to an owner operator when he gets the phone call that his in-chassis rebuild will now be an out-of-chassis rebuild that costs about $10,000 more. But, if there is a problem with the lower counter bores, the cylinder block needs resurfacing, the line bore needs to be redone or the crankshaft has a problem, an out-of-frame will be required. When money (or time) is an object, a quick fix to the lower counter bore, if the corrosion isn’t too bad, might be JB Weld or Liquid Steel. Clean the cavitation with a wire wheel, blow out the dust with an air gun, and wipe the area with lacquer thinner or brake cleaner. With your fingertip, fill the cavitation with the JB Weld or Liquid Steel, allow to dry overnight, and then sand it to the contour of the counter bore. THIS IS NOT a permanent repair, and it should only be performed if the cavitation is smaller than the size of a dime. However, this will get the engine back together, at minimal expense, so the owner can get back to work. If the engine block needs to be resurfaced and line bored then, by all means, repair the lower counter bores the proper way with new inserts.

It’s never welcomed news to an owner operator when he gets the phone call that his in-chassis rebuild will now be an out-of-chassis rebuild that costs about $10,000 more. But, if there is a problem with the lower counter bores, the cylinder block needs resurfacing, the line bore needs to be redone or the crankshaft has a problem, an out-of-frame will be required. When money (or time) is an object, a quick fix to the lower counter bore, if the corrosion isn’t too bad, might be JB Weld or Liquid Steel. Clean the cavitation with a wire wheel, blow out the dust with an air gun, and wipe the area with lacquer thinner or brake cleaner. With your fingertip, fill the cavitation with the JB Weld or Liquid Steel, allow to dry overnight, and then sand it to the contour of the counter bore. THIS IS NOT a permanent repair, and it should only be performed if the cavitation is smaller than the size of a dime. However, this will get the engine back together, at minimal expense, so the owner can get back to work. If the engine block needs to be resurfaced and line bored then, by all means, repair the lower counter bores the proper way with new inserts.

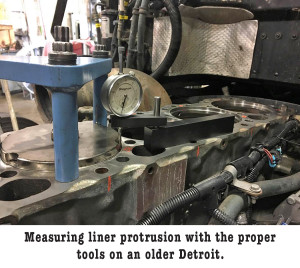

We have talked about upper counter bores and liner protrusion many times over the past few years, and to this day we keep getting phone calls from owner operators with blown head gaskets shortly after an in-frame rebuild. We ask the question, “What was the liner protrusion set to when the engine was rebuilt?” The answer we always get is, “I don’t know,” or, “It’s within spec.” I’m sorry to say, but the factory specs are too low to hold a head gasket for 500,000 miles. You will want your liner protrusion to be set at .001 higher than what the book calls for. So, if the spec is .003 to .006, you should have the protrusion set at .007. Some of the engine manufactures will say zero to .004 – if that is the case, then the protrusion should be set at .005.

We have talked about upper counter bores and liner protrusion many times over the past few years, and to this day we keep getting phone calls from owner operators with blown head gaskets shortly after an in-frame rebuild. We ask the question, “What was the liner protrusion set to when the engine was rebuilt?” The answer we always get is, “I don’t know,” or, “It’s within spec.” I’m sorry to say, but the factory specs are too low to hold a head gasket for 500,000 miles. You will want your liner protrusion to be set at .001 higher than what the book calls for. So, if the spec is .003 to .006, you should have the protrusion set at .007. Some of the engine manufactures will say zero to .004 – if that is the case, then the protrusion should be set at .005.

If you are having your engine rebuilt by someone and they do not now the spec, it’s up to the rebuilding mechanic to look it up in the engine manual or online. You, as the owner of the truck, should tell the mechanic you want to know the liner protrusion of each cylinder, and it should be written down as the mechanic is cutting and installing the liner shim and checking the protrusion. It’s more time-consuming on a Caterpillar because of the deck plate. The gasket under the deck plate must be installed under the plate and the plate must be torqued down to 100 foot-pounds. The same goes for all engines – the liners must be torqued down to 100 foot-pounds to obtain a true measurement.

Even if the engine has 400,000 miles since the last rebuild and the head gasket blows, some mechanics will remove the head and gasket, clean the block, check the liner protrusion with a dial indicator, and then say the protrusion is off by .003 from side to side. This is because he DID NOT install the proper liner hold down bolts and torque the liners down to 100 foot-pounds. Always ask the mechanic the right questions when he gives you the spec, if he can give you the spec. The proper dial indicator tool used for checking liner protrusion has a base that is about 10 inches long, so it takes irregularities along the block into account. A standard magnetic dial indicator base will NOT give you the proper reading.

Even if the engine has 400,000 miles since the last rebuild and the head gasket blows, some mechanics will remove the head and gasket, clean the block, check the liner protrusion with a dial indicator, and then say the protrusion is off by .003 from side to side. This is because he DID NOT install the proper liner hold down bolts and torque the liners down to 100 foot-pounds. Always ask the mechanic the right questions when he gives you the spec, if he can give you the spec. The proper dial indicator tool used for checking liner protrusion has a base that is about 10 inches long, so it takes irregularities along the block into account. A standard magnetic dial indicator base will NOT give you the proper reading.

The tool for cutting the upper counter bores is several thousand dollars and most mechanics will not have it, or the cutting plate, for all the engines he has to work on. You should ask if he has the proper tools to perform the task before he starts rebuilding your engine. If he doesn’t, you might consider taking your truck to another shop. These older engines are great, but they still need to be rebuilt properly to give you trouble-free service for years. If you have any comments or questions, I can be reached through Pittsburgh Power in Saxonburg, PA at (724) 360-4080.