We have talked about high-flow exhaust manifolds many times over the years. To make these manifolds accomplish their task of providing more power and more efficiency, we engineered them on a flow bench, where we could see our designs in action, and see (and measure) the flow increase. Focusing on the bends, most of the manifolds out there have 90-degree bends, and exhaust does not like to flow around 90-degree turns. To correct this flaw, our Full Tilt Pittsburgh Power manifold was designed with 45-degree bends to increase the flow – and it works!

We have talked about high-flow exhaust manifolds many times over the years. To make these manifolds accomplish their task of providing more power and more efficiency, we engineered them on a flow bench, where we could see our designs in action, and see (and measure) the flow increase. Focusing on the bends, most of the manifolds out there have 90-degree bends, and exhaust does not like to flow around 90-degree turns. To correct this flaw, our Full Tilt Pittsburgh Power manifold was designed with 45-degree bends to increase the flow – and it works!

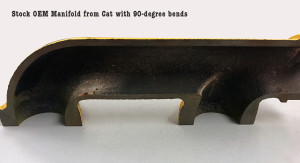

To help show you the differences, I took some pictures of the Full Tilt Pittsburgh Power High Flow Exhaust Manifold, along with a manifold from another manufacturer and a stock OEM manifold. I realize looking at the pictures it’s hard to see, but our manifold is 20% larger on the inside diameter, but you can easily see Full Tilt has eliminated the 90-degree bends and made all of them 45 degrees. Keep in mind that a 90-degree turn in the intake piping, exhaust piping and fuel lines, is equivalent to 13 feet of straight pipe. Exhaust does not like to flow around 90-degree turns. With the Full Tilt manifold on your engine, the fuel mileage will improve by one-quarter mpg, the exhaust gas temperature will decrease by 125 degrees, and the throttle response will be quicker.

Another benefit about the Full Tilt Pittsburgh Power manifold is that they are made in the USA using cast iron from our country. It’s a proven fact that cast iron from China is NOT as strong as the cast iron made in the USA. Why do you think the diesel engine industry is having so many cracked heads and cracked exhaust manifolds? All the OEM castings are now from China. That is another reason we at Pittsburgh Power prefer to install 180-degree thermostats on the engines we build – to try and keep the cylinder head cooler to avoid cracking. The turbine housings on turbos are also cast in China and, yes, there are more of those being cracked since 2003 than in the history of the diesel engine. Any time you can have USA cast iron, the longevity of the part is much longer.

Another benefit about the Full Tilt Pittsburgh Power manifold is that they are made in the USA using cast iron from our country. It’s a proven fact that cast iron from China is NOT as strong as the cast iron made in the USA. Why do you think the diesel engine industry is having so many cracked heads and cracked exhaust manifolds? All the OEM castings are now from China. That is another reason we at Pittsburgh Power prefer to install 180-degree thermostats on the engines we build – to try and keep the cylinder head cooler to avoid cracking. The turbine housings on turbos are also cast in China and, yes, there are more of those being cracked since 2003 than in the history of the diesel engine. Any time you can have USA cast iron, the longevity of the part is much longer.

For many years the diesel engine in the semi-truck and the Dodge Cummins pickup truck was the emphasis of our work. Eleven years ago, when we moved into our new facility, we started working on transmissions, clutches and drive shafts. Later, we continued to expand our operation into the electronics of the engine and the MD Alignment System. As it turns out, when doing wheel alignments, you will find worn-out suspension components, so now we do some suspension work, as well, along with brakes, drums and, of course, the entire electrical system of the truck. Many of the mechanics we have today are well-versed on the entire mechanical aspect of the semi-truck. It just became a natural evolution to continue to do more mechanical repairs on the truck.

To help illustrate the extensive amount of repairs we now perform, the following is a list of the work we are currently doing on a ISX-powered 2006 Volvo 880 with 1.3 million miles on the odometer: the engine fan groans and the belts squeal when the fan comes on; oil pressure is down 17 pounds of pressure since the customer had a new oil pan installed; replace the oil pump pick-up tube which was hit at one time from a broken rod with the previous owner; replace the block stiffener plate, which was also distorted from the broken rod; replace the water pump; inspect the rod and main bearings; replace the radiator; replace the fittings on the air compressor and check for air leaks; and we’re not done yet.

To help illustrate the extensive amount of repairs we now perform, the following is a list of the work we are currently doing on a ISX-powered 2006 Volvo 880 with 1.3 million miles on the odometer: the engine fan groans and the belts squeal when the fan comes on; oil pressure is down 17 pounds of pressure since the customer had a new oil pan installed; replace the oil pump pick-up tube which was hit at one time from a broken rod with the previous owner; replace the block stiffener plate, which was also distorted from the broken rod; replace the water pump; inspect the rod and main bearings; replace the radiator; replace the fittings on the air compressor and check for air leaks; and we’re not done yet.

We also plan to rebuild the drive shaft and then balance and straighten it; replace the U-joints and carrier bearing; replace the steering shaft; move the exhaust stack to the other side; install load lock racks; install a new pyrometer; tune the engine and make a dyno run; lower the parameter for the engine fan to come on five degrees sooner; verify the RPM reading on the Kevin Rutherford scan gauge; inspect the input shaft speed sensors, barometric pressure sensor, turbo boost sensor, leaking turbo air control valve, turbo speed sensor, Delta P sensor, I.M.A.P. sensor, exhaust pressure sensor and coolant temp sensor; replace the leveling valves, cab and engine mounts; check the power divider and rear differentials and replace the rear brakes. The bearings were turning on the axle spindles, so we must also replace the axle housings or have the Axle Surgeons come out and replace the spindles.

This is quite a list of repairs – possibly, the most extensive list of repairs ever performed at one time on a truck in our shop! Sometimes, an owner operator will purchase a used truck and leave it at our shop with a long list of repairs, however we usually have that truck for about 2 to 3 months to make it right. The above-mentioned job is going to be completed in about 2 weeks. Like I have always said, “Take care of the truck that takes care of you!” Your truck is an investment and a vital part of your business – spend (invest) money in it now, and the dividends will come, probably sooner than later. If you have questions, I can be reached at Pittsburgh Power in Saxonburg, PA by calling (724) 360-4080.