It goes without saying that trucks have increased in complexity over the years. We went from engines with a handful of wires to what manufacturers call “systems” – not engines. Two main complaints I hear about new trucks are the aftertreatment and all the electronics. The truth is neither is going away.

The electronics on a truck consist of a module, or computer, for almost everything on your truck, and wires that connect them. Each module communicates with other modules to perform specific tasks. For example, one module might recognize that a switch has been engaged. It sends a message to another module stating that “this switch has been engaged.” The module receiving the message can turn on lights or any other electrical component. This system works well but relies on nearly perfect data transmission from one module to another. The wires that connect these modules carry important data, so it is imperative that the messages are delivered safely.

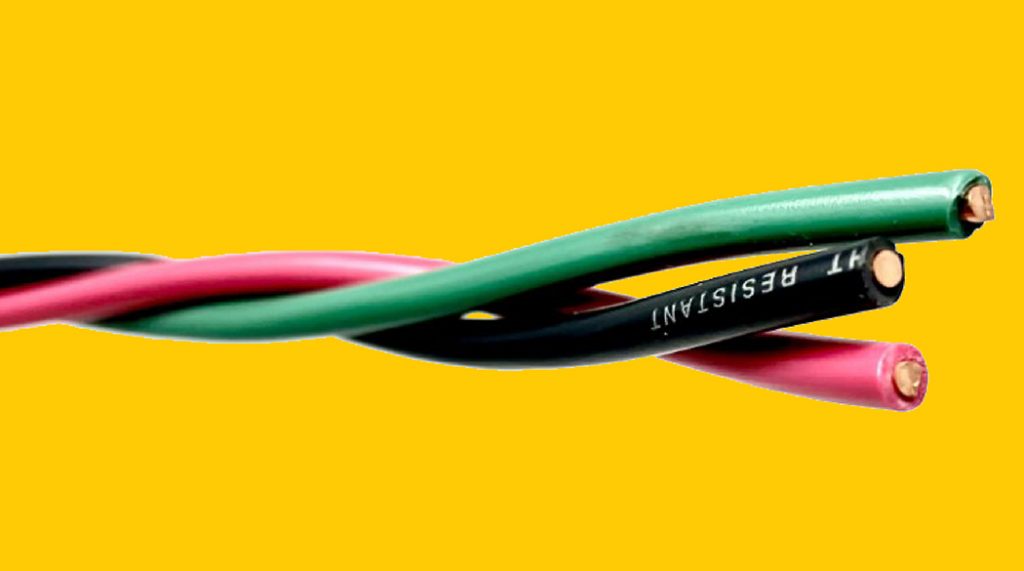

A port, which is commonly green or black, on your dash, allows technicians to connect their laptops to the truck’s modules. If you have ever looked at the wires that go to your data port, you will notice the wires are twisted. You may have also seen that speed sensor wires are also twisted. Examples of some speed sensors are crank position, camshaft position, and vehicle speed sensors. What these sensors all have in common is that they carry a signal.

A signal here can be defined as a repeating electrical pulse. Putting these signals on a wire can act like a weak antenna. Antennas, like the ones we used to have with CB radios, can transmit messages over long distances. The same scenario happens with your truck’s modules and wiring, but on a smaller scale. The modules on trucks don’t output enough power to send messages over long distances. However, they possess enough power to transmit short distances to other wires. This unintentional transmission of signals across wires is called electromagnetic interference (EMI) or noise.

Imagine the wiring in your truck like the highway, and the cars on the highway are like signals. EMI is like when a car swerves from the adjacent lane into your lane. This can cause an accident, back up traffic, or sometimes, you will miss an exit if you’re not in the correct lane. When signals jump from one wire to another, the modules that read these signals can’t make sense of the message or can lose a message, just like missing an exit. To prevent this, designers can employ a few different techniques to prevent these electrical traffic accidents from occurring.

One way to protect these signals from crossing is to shield the wire. This usually is done with a ground wire or a conductive material that covers the wire. This can shield or block unwanted signals from entering the wire. The other method often used in our trucks is twisting the wires together. These twisted wires act like noise-canceling headphones. Noise-canceling headphones listen to outside noise and create an opposite noise that “cancels” the noise. Another way to think of it is to imagine you have $10 in your wallet but owe the parking attendant $10. This basically means you have zero dollars in your wallet. The equal plus and minus cancel each other out.

The reduction in this noise is crucial for important signal communications. When your engine’s ECM communicates with the transmission control module to make a shift, the transmission needs to receive messages like engine speed or throttle position. You don’t want the transmission to make a mistake going down the road at 50 mph. Mixed or diluted signals are known as cross-talk. It is like sitting at a noisy restaurant and trying to have a conversation. It is easy to miss parts of the conversation or incorrectly hear something the other person didn’t say. Twisting wires helps to eliminate noise and keep the module’s “conversations” clear.

Keep in mind that not all wires need to be twisted. This wiring technique is basically only seen on data wires and speed sensor wires in your truck’s wiring. If you are rewiring these circuits yourself, it is important to understand why it must be done. Like a skilled driver that navigates the road, your truck’s wiring needs a clear path to reach its destination, otherwise disastrous events could occur.

I would like to thank Leroy Pershing here at Pittsburgh Power for writing the article this month. He is a super smart guy, and if you have issues with your truck’s wiring, give him a call at (724) 360-4080 or stop by our shop in Saxonburg, PA and talk to someone in person. To see all our available parts and services that can make your truck run better, be more efficient, more powerful, and more fun to drive, check out our website at www.pittsburghpower.com anytime.