Diecast and plastic truck models are common these days, but it’s not often you see a fully CNC machined, billet aluminum, tractor-trailer combo! Trent Van Bronkhorst (25) of Jenison, MI is the brilliant young man that designed, created, and built this metal marvel – a totally custom 1:32 scale 1980 Kenworth K100 hooked to a 1999 Great Dane spread-axle reefer trailer. Working on the project at his place of employment on nights and weekends, using just scraps left behind from the company’s actual work orders, the project took over two years for Trent to complete.

Finding us online, Trent enjoys reading 10-4 Magazine. After finishing this project, he reached out to us and shared what he had created – and we loved it! His father Dan drove truck for a short while, along with farming, but Trent doesn’t have a huge connection to the trucking industry. Growing up, Trent had a lot of toy trucks, he loved building things with Legos (mostly trucks), and he went trucking with his father whenever he could. And the truck his dad drove back then was a Kenworth K100 cabover, similar to the one he made.

While still a senior in high school, Trent got a job at a large automation company, sweeping the floors. Heading off to college to study engineering after high school, Trent ended up getting two degrees – one in Mechanical Design and another in Product Design Engineering. Trent’s first truck project was done in college. Studying solid modeling, he made a CAD (Computer-Aided Design) model of a Peterbilt 379. Later, the school 3D printed the truck, and to this day, they have it on display at the school and use it as a recruitment tool.

Between school semesters, Trent would do some ag trucking (no CDL needed) with some relatives that run a wheat farm operation in North Dakota. Trent loves driving trucks and hopes to one day do some moonlighting for fun and extra money, while continuing his career in product manufacturing and engineering. He loves creating things, and this career, although just getting started, has proven to be a rewarding choice for his skills and talents.

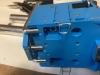

After getting out of school, while working at the automation company, he began working on this project at night and on weekends. Using scraps of ATP-5 and 6061 billet aluminum from actual jobs the company was doing for their clients, Trent began by first building the trailer – a replica of a 53’ 1999 Great Dane reefer trailer, with a 12’ spread, and fitted with a Thermo King SB-III unit. The entire combination was designed in a 1:32 scale and was precisely designed as a solid by Trent, using CAD software, and then that data was imported into a CAM (Computer-Aided Manufacturing) program, which tells the CNC machine what to do. CNC stands for Computer Numerical Control, and it is the process used to make solid metal objects.

With each piece basically being a prototype, the process was very time consuming. The project began in March 2020 and was completed in April 2022, with an estimated 400 hours of actual work. Everything on this model was machined, except a few “wires” that were used for small parts like mirror brackets, grab handles, and windshield wipers, just to name a few. And no adhesives were used whatsoever – every piece of the model is either screwed together or was machined with a tight enough tolerance to allow pieces to be pushed together and hold.

After building the trailer, Trent went to work on the frame of the truck, which proved to be the most complicated piece of them all. Almost everything had to be machined and made to bolt on to that piece, and many of the individual parts required several setups on the CNC machine. Then, after everything was made, Trent hand-painted or airbrushed many of the parts, and hand polished a few, as well. He even hand-built the case the rig resides in, creating a machined aluminum base, fitted with a plexiglass cover, that bolts down on each corner.

A few months after the project was completed, Trent entered it into the world’s largest annual art event called ArtPrize, which is held every year in Grand Rapids, MI, and won a prize. This event goes on for over two weeks and encompasses over three square miles of space in Grand Rapids. In 2022, over 750 artists participated, and hundreds of thousands of visitors attended to check out the competition. It’s a pretty big deal! Needing to come up with a name for his project, he called it “Jake in the Box” – sort of a play on words, since the truck is a cabover (basically a box), and most rigs have Jake brakes.

Since completing the project and impressing his superiors at work, they have asked Trent to make various things for them such as plaques, trophies, and custom retirement gifts. And although he began by sweeping the floors, today his title is Manufacturing Specialist. Working with engineers as a consultant to the design and manufacturing teams, Trent helps the teams to work together to better serve their clients in automating their manufacturing processes.

When asked if he would do this all over again, his answer was a resounding, “Yes!” Trent has lots of ideas floating around in his head, but no projects planned, just yet. In addition to working hard at his job and climbing the ladder of success, Trent also enjoys music, and has been a drummer for many years. Not a member of any particular group, Trent plays in a lot of church bands, performing contemporary Christian music, and really enjoys it. He wanted to send out a big “thank you” to his entire family for their ongoing support and encouragement, and especially to his dad, for passing him the trucking bug, and a good work ethic.

If you want to see this amazing truck and trailer in person, Trent Van Bronkhorst has agreed to bring it to the Mid-America Trucking Show (MATS) in Louisville, KY at the end of March and display it in our booth. Trent will be on-hand in our booth (#11268 in the North Wing) at times, to show you the truck and answer questions. We are so glad he reached out to us and allowed us to share this amazing project with all of you, and we can’t wait to see this metal marvel up close and in-person.