Repair shops struggle as the scarcity of replacement parts are keeping trucks in shops and drivers in waiting rooms. Here at Pittsburgh Power, we are also feeling the impact of these shortages. It is maddening to know the issue but are unable to perform repairs because we can’t get parts. Detroit’s One Box and the SCR catalyst for Cummins engines are among the many parts that are currently unavailable. In a few paragraphs, in an effort to help you extend the life of your system, I will briefly describe the parts of the SCR system that fail and what can be done to prolong the life of these parts.

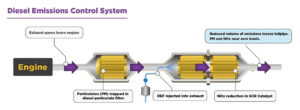

An SCR (selective catalyst reduction) is used in the aftertreatment system to reduce NOx emissions. In the past, the primary mechanism to reduce NOx emissions was EGR. While EGR is effective for reducing NOx, it also has downsides. The use of SCR allows the engine to run more efficiently while maintaining modern emission standards. Most trucks can go 600,000 to 700,000 miles before the catalyst wears out or deactivates. A deactivated catalyst is OEM speak for a worn-out catalyst. Basically, it means that the SCR has reached the point where it can no longer efficiently remove NOx.

As the SCR ages the system must inject more DEF to keep the same NOx removal rate. At some point, the catalyst will have too much ammonia slip and will have to be replaced. Dosing too much DEF at this point could also damage the system with urea deposits. Ammonia slip (NH3 slip) refers to how much unprocessed DEF leaves the tailpipe. Ammonia is not a regulated pollutant, but its environmental effects are known and should be minimized.

Some ISX engines were equipped with a NH3 sensor in the middle of the SCR. This sensor monitors the quantity of ammonia to determine a NH3 to NOx ratio or ANR. When urea is injected into the exhaust it is broken down to create ammonia. The SCR uses this ammonia to convert NOx into N2 and O2. Once the exhaust temperature, at the SCR inlet, reaches roughly 200⁰C or 392⁰F the system will allow DEF to be injected. If DEF is injected before this, unacceptable amounts of ammonia will slip through the catalyst and into the atmosphere. Excess NH3 is harmful to the environment and your system. Many of you have seen DEF buildup in the exhaust and have been parked due to it. A complex control strategy in the ECM is used to keep the balance between optimal NOx reduction, NH3 slip, and preventing build up.

Catalysts wear out for various reasons such as poisoning, fouling, or old age. You can do a few things to maximize the in-use time for your SCR system. Firstly, make sure your engine doesn’t burn an excessive amount of oil. Engine oil contains additives that poison catalysts. Phosphorous or zinc additives, like zinc diethyldithiophosphate (ZDDP), that are anti-wear additives, are possibly the most harmful to catalysts. Use caution when adding these additives to your oil and be sure to dose the recommended amount. Unburnt oil and additives coat the face of the catalyst forming a permanent glaze that prevents the SCR from doing its job. Usually, once these catalysts are poisoned, the damage is irreversible.

Another major factor that decreases catalyst life is fouling. An example of fouling would be a malfunctioning DEF injector that leaks fluid into the exhaust stream. If the exhaust temperature is not high enough to decompose the urea, buildup could occur. Your DEF injector should be periodically tested to prevent unwanted catalyst fouling compounds such as ammonium nitrate, ammonium sulfate, or unhydrolyzed urea. The good news is when you have a buildup of these compounds the damage is reversible. SCR deposits will break down at around 900-1100 degrees. Your system will reach these temperatures during a typical filter regeneration. Like everything else on your truck, these systems wear out over time from normal use. I frequently use the analogy that they are like tires – you can do your best to keep them in shape, but eventually they will need to be replaced.

We are happy to announce Winterized Max Mileage is now available! It’s 50% Max Mileage and 50% antigel/deicer. The cost is $145 and dosage doubles to two ounces per 25 gallons. Diesel Guard by ValveTect is one of the best winter additives on the market. It’s super concentrated which is what allowed us to use it in conjunction with Max Mileage. It’s effective below -30°F but reduces the freeze point to -50°F. Not only will it allow your truck to start on the coldest mornings, but it will protect your engine during the harsh winter conditions by increasing lubricity and protecting against corrosion. We encourage you to buy a gallon and have it on-hand when the weather takes a turn. Last year, antigel was difficult to find, and it will probably be worse this year. But we’ve got you covered with Winterized Max Mileage.

Regarding shortages, it is common knowledge that there will soon be a shortage of oil, which is predicted to get worse over the next few months. Oil change prices are going up, and our bulk engine oil suppliers are even limiting how much we can buy. One solution is to install one of our OPS systems on your truck. With OPS, you can safely extend oil drains while sampling every 25,000 miles. If your sample comes back clean, you’re not wasting perfectly good oil with an unnecessary oil change. If the oil sample comes back questionable, we’ll give you a call and walk you through the options. It’s always better to catch engine problems early. With the price of oil rising, the OPS system will pay for itself in a year, and prevent issues caused by dirty oil.

Got questions? Stop by our shop in Saxonburg, PA, call us at (724) 360-4080, or visit us at www.pittsburghpower.com. Thanks to Andrew Wilson and Leroy Pershing for their help in writing this article.