When you hear Pittsburgh Power what comes to mind? Is it our service shop, our ECM tunes or maybe our engine rebuilds? We recently realized we actually have eight businesses all wrapped up in one. We are first and foremost a diesel repair shop, but we’re also an engineering and tuning shop, a manufacturer, a bottling company, a parts distributor, a brick and mortar retailer, a phone retailer and an online retailer. Many businesses exist that are just one of these things, but we do it all. As of this year, we’ve been in business for 43 years, and wanted to reflect back and figure out how we got here.

When you hear Pittsburgh Power what comes to mind? Is it our service shop, our ECM tunes or maybe our engine rebuilds? We recently realized we actually have eight businesses all wrapped up in one. We are first and foremost a diesel repair shop, but we’re also an engineering and tuning shop, a manufacturer, a bottling company, a parts distributor, a brick and mortar retailer, a phone retailer and an online retailer. Many businesses exist that are just one of these things, but we do it all. As of this year, we’ve been in business for 43 years, and wanted to reflect back and figure out how we got here.

The service shop was the original business. In 1977, I was given a small shop in Lawrenceville, PA – an old neighborhood just north of downtown Pittsburgh. Today, it’s a trendy area with breweries and restaurants, but back then it was just a cheap place to live and work. The shop was so small you couldn’t fit a truck inside, so I worked on the trucks outside, even in the freezing  winters. In 1979 I was able to rent a building with a garage in Harmar, PA. We taught ourselves as we went, looking at each new customer request as a challenge. We worked on all sorts of things, even tractors, until we honed-in on what we were best at, which is high performance diesel truck engines.

winters. In 1979 I was able to rent a building with a garage in Harmar, PA. We taught ourselves as we went, looking at each new customer request as a challenge. We worked on all sorts of things, even tractors, until we honed-in on what we were best at, which is high performance diesel truck engines.

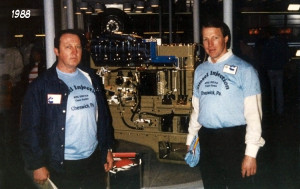

Early on I hired a few young folks to work for me, like Brian (shop foreman), Pete (general manager), Pat (injector and fuel pump rebuilder), Gary (still helps with our IT) and Aimee who works in the office. The five of them and I built this business together over the last four decades. We gained a reputation as the place to go for high performance diesels, especially Cummins, due to my connection with their engineers. In 2007 we moved into our new location – a building built from scratch to suit our needs – which has allowed us to grow all the other parts of our business. Today, we work on all sorts of engines, but remain the go-to shop for Big Cam Cummins parts and service.

Our Engineering Department was created out of demand from our customers. As trucks became less mechanical, very few shops were able to understand and fix their complex electronic problems. In addition, these new electronically controlled engines offered tuning capabilities the old mechanical engines didn’t. Instead of changing the button in a fuel pump, it now just takes a few clicks on the computer to adjust a torque curve. We saw how valuable this could be and decided to add a full chassis dyno and engine dyno to our building, as well as an engineering room for repairing ECMs and other electronics.

Our Engineering Department was created out of demand from our customers. As trucks became less mechanical, very few shops were able to understand and fix their complex electronic problems. In addition, these new electronically controlled engines offered tuning capabilities the old mechanical engines didn’t. Instead of changing the button in a fuel pump, it now just takes a few clicks on the computer to adjust a torque curve. We saw how valuable this could be and decided to add a full chassis dyno and engine dyno to our building, as well as an engineering room for repairing ECMs and other electronics.

It’s surprising how many shops still can’t diagnose and/or fix electrical issues. We had a customer that had a broken cruise control and had been to three other shops who charged him labor but couldn’t fix the problem. Ethan was able to diagnose and fix this customer’s problem in less than an hour. Recently, we started working with one of the world’s most experienced engine tuners to expand our program. We’re now ready to start tuning Paccar, Volvo and Mack engines. Our new advanced software will allow us much greater tuning capability to meet the needs of owner operators everywhere.

Many of the products we’ve developed and manufactured were because we either were not satisfied with the available products or we saw a need for something new. Pete designed our best-selling quiet performance muffler that continues to be a customer favorite. There are many other products we developed along the way, including the Power Box, the oil trap, our torsional damper, the mercury filled balancer and more. We’re constantly looking for new products that will help the owner operator to enjoy driving their truck more.

Many of the products we’ve developed and manufactured were because we either were not satisfied with the available products or we saw a need for something new. Pete designed our best-selling quiet performance muffler that continues to be a customer favorite. There are many other products we developed along the way, including the Power Box, the oil trap, our torsional damper, the mercury filled balancer and more. We’re constantly looking for new products that will help the owner operator to enjoy driving their truck more.

One of the successful products we’ve brought to market is our Max Mileage Fuel Borne Catalyst. It’s one of the best solutions for those who have had issues with their after-treatment systems. We underestimated the need for this product at the beginning and had trouble keeping enough inventory. The only solution was to bottle it ourselves. We really didn’t know anything about bottling and didn’t realize how much goes into it. But, with some help, we got it figured out, and now we can easily keep up with the huge demand.

We’re also a parts distributor and have a vast network of dealers for both ECM tuning and parts. We have roughly 70 affiliated partner shops around the country and Canada that are either a remote tuner, a fuel catalyst dealer, a parts dealer or all of the above. Our shipping department is quite an intensive operation, handling drop shipments, online orders and receiving parts for the service shop.

We’re also a parts distributor and have a vast network of dealers for both ECM tuning and parts. We have roughly 70 affiliated partner shops around the country and Canada that are either a remote tuner, a fuel catalyst dealer, a parts dealer or all of the above. Our shipping department is quite an intensive operation, handling drop shipments, online orders and receiving parts for the service shop.

Our sales operation takes three forms – phone, in-store and online. We’ve seen massive online sales growth within the last year as more customers see the advantage of ordering 24/7 from anywhere. Even so, many folks still prefer to call, and appreciate the knowledge and helpfulness of our sales team. Our over-the-counter parts sales are utilized by many local diesel shops who take advantage of our vast inventory of parts. Our sales business has allowed us to serve owner operators globally, selling parts from the U.K. to Australia.

We are grateful for all our stakeholders, including our partner businesses, our employees and especially our customers. If you would like to stay updated on what we’re doing, besides reading this article each month in 10-4 (since 2002), you can also follow us on Facebook and Instagram, visit our website (www.pittsburghpower.com), or listen to the Power Hour radio show on Sirius/XM channel 146 each and every Tuesday from 12-2 EST. If you are visiting the Mid-America Trucking Show in Louisville, KY, come see us at booth #69212 in the West Wing. We look forward to serving you and the entire trucking industry for many more years to come! Thank you!!

We are grateful for all our stakeholders, including our partner businesses, our employees and especially our customers. If you would like to stay updated on what we’re doing, besides reading this article each month in 10-4 (since 2002), you can also follow us on Facebook and Instagram, visit our website (www.pittsburghpower.com), or listen to the Power Hour radio show on Sirius/XM channel 146 each and every Tuesday from 12-2 EST. If you are visiting the Mid-America Trucking Show in Louisville, KY, come see us at booth #69212 in the West Wing. We look forward to serving you and the entire trucking industry for many more years to come! Thank you!!