If you’ve listened to our radio show, the Pittsburgh Power Hour on Road Dog Trucking Sirius/XM Ch. 146, you would know how difficult it can be to diagnose a problem over the phone. Recently, we had a customer call who’s 2007 Detroit DDEC-V equipped car hauler was experiencing a loss in power and fuel mileage. The truck was struggling on the hills and returning an abysmal 4.3 MPG. The owner operator was keen enough to have a boost gauge installed, and noticed the VG turbo was running at 30 pounds of boost on level ground at 65 MPH. Obviously, there is a serious issue here, because it should be at 8-10 pounds of boost, but what could it be?

If you’ve listened to our radio show, the Pittsburgh Power Hour on Road Dog Trucking Sirius/XM Ch. 146, you would know how difficult it can be to diagnose a problem over the phone. Recently, we had a customer call who’s 2007 Detroit DDEC-V equipped car hauler was experiencing a loss in power and fuel mileage. The truck was struggling on the hills and returning an abysmal 4.3 MPG. The owner operator was keen enough to have a boost gauge installed, and noticed the VG turbo was running at 30 pounds of boost on level ground at 65 MPH. Obviously, there is a serious issue here, because it should be at 8-10 pounds of boost, but what could it be?

Our lead Engineer, Ethan, said he has seen this happen before. One time he remembered it was caused from a bad tuning program, but, honestly, it could also be an assortment of other mechanical issues causing this loss of power. On that truck, the tune was causing the ECM to put the truck in high altitude mode and running a high level of boost at all times. Most likely it’s the turbo or a bad boost sensor, but it could be caused by almost any other mechanical issue making the truck run poorly. Another possible cause is it could be the variable vanes in the turbo not opening completely due to exhaust soot (our Diesel Force engine cleaning system could eliminate that problem).

Our lead Engineer, Ethan, said he has seen this happen before. One time he remembered it was caused from a bad tuning program, but, honestly, it could also be an assortment of other mechanical issues causing this loss of power. On that truck, the tune was causing the ECM to put the truck in high altitude mode and running a high level of boost at all times. Most likely it’s the turbo or a bad boost sensor, but it could be caused by almost any other mechanical issue making the truck run poorly. Another possible cause is it could be the variable vanes in the turbo not opening completely due to exhaust soot (our Diesel Force engine cleaning system could eliminate that problem).

Diagnosing a problem like this can be like solving a large jigsaw puzzle – there are many small pieces, and they all must fit together to give you the whole picture. In this case, there are not enough pieces of information to give a proper diagnosis – yet. That is why we often suggest owner operators bring their trucks to the shop, because there are only so many tests we can give you over the phone to determine the cause of the problem. The average person may not have the tools to diagnose it themselves. We welcome people to call us with their complicated issues, because that’s our specialty, however many of these problems must be repaired at our shop.

Diagnosing a problem like this can be like solving a large jigsaw puzzle – there are many small pieces, and they all must fit together to give you the whole picture. In this case, there are not enough pieces of information to give a proper diagnosis – yet. That is why we often suggest owner operators bring their trucks to the shop, because there are only so many tests we can give you over the phone to determine the cause of the problem. The average person may not have the tools to diagnose it themselves. We welcome people to call us with their complicated issues, because that’s our specialty, however many of these problems must be repaired at our shop.

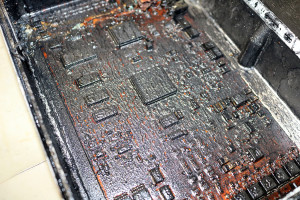

Fans of our social media accounts (Facebook, Instagram and Twitter) know that every week we post a “Fail of the Week” with pictures of a spectacular mechanical failure. Every week we see new ways these trucks we rely on so much are failing. We like to share it with everyone, hopefully helping you all avoid the same mistakes that lead to those failures. This week’s “fail” was a  Detroit ECM that was sent in to us. It looked like a typical ECM on the outside, but on the inside, the circuit board was completely covered in a thick greasy sludge (see photo). We’ve seen this problem before, but not to this degree. The sludge was a mix of oil and fuel dripping off the engine right into the ECM! What happens is the seal on the ECM case breaks and allows debris inside. The customer was not aware this was the cause of the malfunction. Surprisingly, Ethan was able to clean the sludge off and repair the ECM. So, during your routine mechanical checks, look at the ECM and make sure it’s staying as clean and dry as possible.

Detroit ECM that was sent in to us. It looked like a typical ECM on the outside, but on the inside, the circuit board was completely covered in a thick greasy sludge (see photo). We’ve seen this problem before, but not to this degree. The sludge was a mix of oil and fuel dripping off the engine right into the ECM! What happens is the seal on the ECM case breaks and allows debris inside. The customer was not aware this was the cause of the malfunction. Surprisingly, Ethan was able to clean the sludge off and repair the ECM. So, during your routine mechanical checks, look at the ECM and make sure it’s staying as clean and dry as possible.

Some of my favorite topics are mercury-filled engine balancers and torsional dampers, and the ignorance that goes with them. I have been preaching about these parts of the engine since my first article in 1989, but many mechanics are still ignorant of what these two parts do. The torsional damper on the front of the crankshaft absorbs torsional twisting of the crankshaft and camshaft. By eliminating the torsional twisting, the engine will pull more consistently and smoother, and help eliminate breakage of AC compressor brackets and alternator brackets, knocking springs out  of clutch discs, eliminate the breaking of transmission input shafts, flywheel bolts and flywheel housing bolts. This part does so much, and most mechanics say, “We never change this harmonic balancer.” Truth is, most mechanics don’t even know the correct name of this part!

of clutch discs, eliminate the breaking of transmission input shafts, flywheel bolts and flywheel housing bolts. This part does so much, and most mechanics say, “We never change this harmonic balancer.” Truth is, most mechanics don’t even know the correct name of this part!

About two months ago I had a phone call from an older owner operator with a 379 Peterbilt powered by a DD4 Detroit who heard a noise coming from the front of the engine, which had just been rebuilt by a Detroit shop 140,000 miles prior. This engine had over one million miles on the bull gear and the damper, but the owner was not informed by the mechanic or shop foreman that the parts needed to be changed. As you can see in some the pictures, the damper is old, rusted and original, and both gears are stripped. These dampers are ONLY good for 500,000 miles or 10 years. The silicone inside that “dampens” the large steel ring that floats in the housing becomes hard and stops the movement of the absorption ring. Now, something on the truck will become sacrificial and break, and your body will begin to absorb the vibrations right up through the seat,  pedals and steering wheel. The shifter will rattle, the door locks will vibrate, and the mirrors and antennas will shake. Sometimes, the mirrors shake so bad you can’t use them to even back up. That is how important this torsional damper is, and 99% of the shop foremans and mechanics out there don’t know about it.

pedals and steering wheel. The shifter will rattle, the door locks will vibrate, and the mirrors and antennas will shake. Sometimes, the mirrors shake so bad you can’t use them to even back up. That is how important this torsional damper is, and 99% of the shop foremans and mechanics out there don’t know about it.

If the mechanic working on your engine says, “We never change the harmonic balancer,” take your truck to another shop. The stripped gears pictured here are the result of the faulty damper which, as you can see, is worn out. If you’re a nickel squeezer and won’t replace parts until it’s too late, the cost of repair is catastrophic. Being cheap with the piece of equipment that makes your living possible is a direct route to disaster. If you have comments or questions, I can be reached at Pittsburgh Power in Saxonburg, PA at (724) 360-4080. Or visit www.pittsburghpower.com to see all are available parts and services.