Precision and balance is important when it comes to your engine. We just ordered six cylinder packs from Caterpillar for a NXS Acert Cat engine and, as most of you know, the cylinder packs come pre-assembled. Most mechanics just clean the block and slide in the new cylinder packs. But, at Pittsburgh Power, we balance all of the connecting rods and pistons for the engines we build, so we disassembled the cylinder packs, and we were shocked at what we found – three different pistons in six cylinder packs. One piston had brass bushings installed in the wrist pin bore and the other five did not. Three pistons were identical, and three pistons were of a different style. According to the spec sheet from Caterpillar, the pistons can be interchanged, but I (personally) would NOT want to have this in my new engine. Would you?

Precision and balance is important when it comes to your engine. We just ordered six cylinder packs from Caterpillar for a NXS Acert Cat engine and, as most of you know, the cylinder packs come pre-assembled. Most mechanics just clean the block and slide in the new cylinder packs. But, at Pittsburgh Power, we balance all of the connecting rods and pistons for the engines we build, so we disassembled the cylinder packs, and we were shocked at what we found – three different pistons in six cylinder packs. One piston had brass bushings installed in the wrist pin bore and the other five did not. Three pistons were identical, and three pistons were of a different style. According to the spec sheet from Caterpillar, the pistons can be interchanged, but I (personally) would NOT want to have this in my new engine. Would you?

To me, the piston is a very important part of the engine, and I want them to all be the same design and the same weight. So, next we took the six pistons off the connecting rods and we weighed them on a scale that weighs to the gram, which is what we use for balancing pistons and connecting rods. What we found was that the lightest piston was 4076.0 grams and the heaviest was 4194.5 – that is a 118.5-gram difference! To make this weight more visual, so you can better imagine how much 118 grams is, we weighed several Snap-On 3/8” drive sockets and the 15/16” socket came out to 118 grams. That is a pretty big socket, and the difference in the weight between the lightest and heaviest piston out of the six cylinder packs we ordered. If we were not going to balance the pistons and would have left the cylinder packs assembled, we would not have seen the three different pistons and that, along with the difference in weights, would have made this newly-rebuilt engine vibrate badly.

To me, the piston is a very important part of the engine, and I want them to all be the same design and the same weight. So, next we took the six pistons off the connecting rods and we weighed them on a scale that weighs to the gram, which is what we use for balancing pistons and connecting rods. What we found was that the lightest piston was 4076.0 grams and the heaviest was 4194.5 – that is a 118.5-gram difference! To make this weight more visual, so you can better imagine how much 118 grams is, we weighed several Snap-On 3/8” drive sockets and the 15/16” socket came out to 118 grams. That is a pretty big socket, and the difference in the weight between the lightest and heaviest piston out of the six cylinder packs we ordered. If we were not going to balance the pistons and would have left the cylinder packs assembled, we would not have seen the three different pistons and that, along with the difference in weights, would have made this newly-rebuilt engine vibrate badly.

These cylinder packs are going into a good friend of mine’s engine – I started building engines for him when he was 17 years old, and he is now 52 years old. He bought his 2007 Kenworth W900-L new and it has vibrated since the beginning. The vibration actually broke the head off of the #1 main bearing cap bolt while he was out west, so he had a Cat dealer out there rebuild the engine – but it still vibrated. Now, with 412,000 miles on an in-chassis rebuild, the crankshaft broke. He is pulling the engine from the truck at his home in Tennessee and bringing it to our shop. After the out-of-chassis rebuild and balancing of the parts, this engine will be smooooth!

These cylinder packs are going into a good friend of mine’s engine – I started building engines for him when he was 17 years old, and he is now 52 years old. He bought his 2007 Kenworth W900-L new and it has vibrated since the beginning. The vibration actually broke the head off of the #1 main bearing cap bolt while he was out west, so he had a Cat dealer out there rebuild the engine – but it still vibrated. Now, with 412,000 miles on an in-chassis rebuild, the crankshaft broke. He is pulling the engine from the truck at his home in Tennessee and bringing it to our shop. After the out-of-chassis rebuild and balancing of the parts, this engine will be smooooth!

A word to the wise: if you are rebuilding your 1995 through 2009 Caterpillar engine, you just may want to remove the pistons from the liners and connecting rods to see if you have matching pistons, and then take them to a good speed shop and have them balanced. Please don’t think I’m picking on the Caterpillar engine here, I love the 425-B up through the NXS 2007 Acert engine – most of them are very smooth – I just don’t like engines that vibrate. There are plenty of Detroits and Cummins that vibrate, as well, so it’s a good practice to balance the connecting rods and pistons when rebuilding an engine. Sometimes we have to use eighteen Detroit connecting rods to get six that are close enough to balance, so this is not a problem exclusive to Caterpillar.

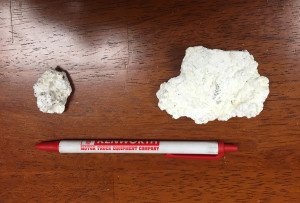

Let’s switch gears and talk about emissions tune-ups for 2012 through 2016 Cummins ISX engines. Recently, we had a beautiful 2015 Peterbilt 386, powered by an ISX Cummins with EGR, DPF and DEF, in our shop for an emissions tune-up and horsepower upgrade. This truck only had 188,000 miles on it, and we found coagulated diesel particulate fluid in the exhaust system – and as seen in one of the pictures, some of these pieces were rather large! We also found a plugged turbo boost sensor, two exhaust pressure sensors, and an EGR differential pressure sensor. The horsepower was increased to 630 to the ground (or 741 at the flywheel) and the torque was increased to 2,000 foot-pounds. Strangely, the stock engine produced 556 hp to the ground and the torque was only 1,400 foot-pounds. So, we only increased the horsepower by 84 to the ground, however, by making the emissions work properly and cleaning out the soot in the intake, the torque increased by 600 foot-pounds. That, my friends, is a shocking increase, and the owner of this truck will be ecstatic with his new-found pulling power.

Let’s switch gears and talk about emissions tune-ups for 2012 through 2016 Cummins ISX engines. Recently, we had a beautiful 2015 Peterbilt 386, powered by an ISX Cummins with EGR, DPF and DEF, in our shop for an emissions tune-up and horsepower upgrade. This truck only had 188,000 miles on it, and we found coagulated diesel particulate fluid in the exhaust system – and as seen in one of the pictures, some of these pieces were rather large! We also found a plugged turbo boost sensor, two exhaust pressure sensors, and an EGR differential pressure sensor. The horsepower was increased to 630 to the ground (or 741 at the flywheel) and the torque was increased to 2,000 foot-pounds. Strangely, the stock engine produced 556 hp to the ground and the torque was only 1,400 foot-pounds. So, we only increased the horsepower by 84 to the ground, however, by making the emissions work properly and cleaning out the soot in the intake, the torque increased by 600 foot-pounds. That, my friends, is a shocking increase, and the owner of this truck will be ecstatic with his new-found pulling power.

Recently, while tuning another EGR-DPF-DEF-equipped ISX (2011 & newer) Cummins, we found similar problems: the decomposition tube where the DEF doser is located, was just about plugged with crystallized diesel particulate fluid. To remove this tube and clean it, we had to completely remove the driveshaft from the truck just to gain access to it. This engine has 389,000 miles and is in a 2012 Peterbilt 587. For the DEF doser to work properly and atomize the DEF fluid, it must be clean and able to spray.

Recently, while tuning another EGR-DPF-DEF-equipped ISX (2011 & newer) Cummins, we found similar problems: the decomposition tube where the DEF doser is located, was just about plugged with crystallized diesel particulate fluid. To remove this tube and clean it, we had to completely remove the driveshaft from the truck just to gain access to it. This engine has 389,000 miles and is in a 2012 Peterbilt 587. For the DEF doser to work properly and atomize the DEF fluid, it must be clean and able to spray.

The emissions systems on these newer engines do run and work properly, however, they need to be tuned and cleaned at least every 250,000 miles. And, if you find yourself rebuilding the engine in your truck, do yourself a favor and make sure to balance all of the rotating parts. If you have any comments or questions, I can be reached at Pittsburgh Power in Saxonburg, PA by calling 724-360-4080.

2 Comments

it is nice to know that you can get your exhaust system done right. This is a big deal what you are making sure that everything is balanced correctly. My brother would love knowing this as he looks for a similar service.

I am a Diesel engine builder in Louisiana, I cannot find a machine shop remotely close to me that will consider balancing my Diesel engine parts. I was wondering if you could direct me to a supplier for balancing equipment so I may just get set up to do my own. I have experience in some race engine balancing with Hines equipment and have not contacted them but hoped to cut through bought mistakes. Time and freight is a factor on most jobs so I think would be worth looking into for us. All help would be greatly appreciated!