The Louisville truck show is now over for another year, and it was wonderful to meet all of our owner operator friends. I must say, this show is like a family reunion, since we have been working the event for the past 25 years. The attendance was down slightly from 81,000 last year to 74,000 this year, and that might have been because the truck manufacturers and engine manufacturers decided to not participate this year. We stayed very busy and did NOT miss the OEM’s – besides, why would you want to purchase a new OEM-built truck with all of the related problems? You can build a brand new truck with a 2002 trouble-free engine that produces 650 to 700 horsepower, will run one million miles, and get great fuel mileage (when properly driven). To me, a glider kit is the most intelligent purchase you can make today.

The Louisville truck show is now over for another year, and it was wonderful to meet all of our owner operator friends. I must say, this show is like a family reunion, since we have been working the event for the past 25 years. The attendance was down slightly from 81,000 last year to 74,000 this year, and that might have been because the truck manufacturers and engine manufacturers decided to not participate this year. We stayed very busy and did NOT miss the OEM’s – besides, why would you want to purchase a new OEM-built truck with all of the related problems? You can build a brand new truck with a 2002 trouble-free engine that produces 650 to 700 horsepower, will run one million miles, and get great fuel mileage (when properly driven). To me, a glider kit is the most intelligent purchase you can make today.

After the show, myself, along with Debbie and two of our engineers, John and Leroy, were invited to tour the PACCAR engine plant in Columbus, Mississippi. We were impressed with what we saw – a spotless, well-organized facility with workers who cared about what they were building. It’s always nice to see people with a good work ethic – after all, isn’t that what built America?

During our tour, the 13-liter engine is what we focused on, and we liked the piston and connecting rod combination, along with the configuration of the head. On this engine, the intake and exhaust valves are offset so the exhaust doesn’t have to push past the valve in front of it, and both intake valves receive the same amount of fresh air. The block and head casting are made out of compacted graphite iron, which is lighter and stronger than cast iron, so the engine is several hundred pounds lighter. Another beautiful item on the PACCAR engine is a Holset turbocharger. Over the years, I have had the privilege of working with several Holset engineers and I have the utmost respect for them and the fine products they produce. Who knows – we may be working on PACCAR engines in the very near future.

Let’s switch gears and talk about the smoking problems with 60 Series Detroit Diesel engines. If you own a 12.7 liter DD4 and the engine is a PK or GK, it will have 15.0 to 1 compression ratio pistons, and if you rebuild it and stay with the OEM parts for that series of engine, you are guaranteed to have horrendous white smoke upon start up until the coolant temperature reaches about 140 degrees. This has happened twice to us, and a client of ours just recently had a Detroit reman engine installed in his new glider kit and he has had the same problem. We spent many thousands of dollars trying to fix this problem on our client’s engine, and finally figured out that the only cure is to build the engine to a BK serial number. The compression ratio of the BK piston is 16.5 to 1 which requires a different camshaft, injectors and Jake Brake.

Let’s switch gears and talk about the smoking problems with 60 Series Detroit Diesel engines. If you own a 12.7 liter DD4 and the engine is a PK or GK, it will have 15.0 to 1 compression ratio pistons, and if you rebuild it and stay with the OEM parts for that series of engine, you are guaranteed to have horrendous white smoke upon start up until the coolant temperature reaches about 140 degrees. This has happened twice to us, and a client of ours just recently had a Detroit reman engine installed in his new glider kit and he has had the same problem. We spent many thousands of dollars trying to fix this problem on our client’s engine, and finally figured out that the only cure is to build the engine to a BK serial number. The compression ratio of the BK piston is 16.5 to 1 which requires a different camshaft, injectors and Jake Brake.

Let’s go back to the 1980s, back when the Big Cam 400 Cummins ran a 14.0 to 1 compression ratio piston and, yes, we had some white smoke until 140 degrees. But, it was just that – white smoke. The PK and GK Detroits have a raw fuel smell along with the white smoke. The raw fuel smell is bad – it will permeate your clothes and you’ll smell like an old diesel engine from back in the 1960s. We love the DD3 and DD4 Detroits, but there is a problem with the OEM parts for PK and GK engines, so we WILL NOT build one – we will convert it to the BK series.

Because of this problem, we have invested in the equipment to “CC” the combustion chamber and the head (this is the process of measuring the volume of the combustion chamber and the head in cubic centimeters). The reason we do this is to find the effective compression ratio of the combustion chamber and the head. Keep in mind, the valves in the 60 Series head are recessed, and on a 4-valve head, that is most of the area of the circumference of the combustion chamber. So, even though the piston is a 16.5 to 1 compression ratio, the effective compression ratio is much less. We know what it is but, unfortunately, can’t say here, because too many other shops are reading these articles and learning from us.

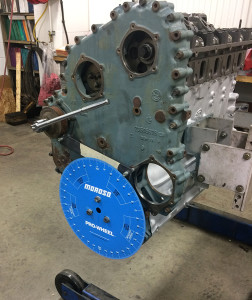

We are determined to figure out this problem and fix it. We have purchased degree wheels, so at the CMC in Council Bluffs, Iowa (or in next month’s article), I will have more information for you about these engines. On a side note, if you have never attended the CMC Live event, I urge you to do so. If you are serious about your trucking business, and want to learn how to make more money, you owe it to yourself to attend this event put on by Kevin Rutherford. For information, visit www.letstruck.com and then click on the “Events” tab or call (855) 800-FUEL.

Next week, we will have a 15.0 to 1 piston from a PK or GK engine in a block and we will CC that combustion chamber. Balancing connecting rods and pistons, CC-ing the combustion chamber and head, degreeing the camshaft, and measuring the crankshaft and rod bearings in the connecting rod is called “blue printing an engine” – and that is how we build them. Please keep in mind that with an overhead cam engine there is a minimal amount of material that can be machined off the block, so we had .012” thicker head gaskets made for the 60 Series Detroit, just in case you need to machine .010 or more metal off the block.

Next week, we will have a 15.0 to 1 piston from a PK or GK engine in a block and we will CC that combustion chamber. Balancing connecting rods and pistons, CC-ing the combustion chamber and head, degreeing the camshaft, and measuring the crankshaft and rod bearings in the connecting rod is called “blue printing an engine” – and that is how we build them. Please keep in mind that with an overhead cam engine there is a minimal amount of material that can be machined off the block, so we had .012” thicker head gaskets made for the 60 Series Detroit, just in case you need to machine .010 or more metal off the block.

Here is another reason to mic the crankshaft and bearing in the connecting rod. An owner operator from Minnesota brought rod and main bearings for us to examine at the Louisville show out of a DD4 Detroit, and they were beat out in only 120,000 miles. He had new bearings installed at a dealership but, now, while under a pull, he has a hammering sound coming from the oil pan. I can say with certainty that his bearings are going to fail again (I suspect that his crankshaft is too small for the standard bearings). As these engines get older, we have to go back to our racing heritage and engine building techniques. Whenever we do an out-of-chassis rebuild on any engine, the crankshaft is magnafluxed, straightened and polished, the block is line bored, and then both are measured with a micrometer, so we do not have these bearing problems.

We have had great success with the BK 60 Series, so please be careful if you are rebuilding your 60 Series and make sure it’s a BK engine. You will have to call your Freightliner dealership or a Detroit dealer with your engine serial number to find out which 60 Series you have. I hope to see many of you at CMC Live on May 16-20 in Council Bluffs, IA. During the event, we will be building a BK 60 Series, and we will show you how to CC the combustion chamber and the head, along with completely rebuilding the engine, from the crankshaft up. You won’t want to miss this! Got comments or questions? I can be reached at Pittsburgh Power in Saxonburg, PA at (724) 360-4080.