We have been doing a lot of work with Detroit’s new DD15 and, so far, it’s been a very good engine for owner operators. We currently had one in the shop with excessive coolant leaks on the exhaust side of the engine (the right/passenger side), and an oil leak on the right rear rocker box housing. The coolant leaks are a result of the gasket that seals the water manifold to the head, which is right behind the exhaust manifold. With these problems in mind, let’s look a little deeper into the bad (and good) things about this new engine, which rumor has it that Detroit spent a billion dollars developing.

We have been doing a lot of work with Detroit’s new DD15 and, so far, it’s been a very good engine for owner operators. We currently had one in the shop with excessive coolant leaks on the exhaust side of the engine (the right/passenger side), and an oil leak on the right rear rocker box housing. The coolant leaks are a result of the gasket that seals the water manifold to the head, which is right behind the exhaust manifold. With these problems in mind, let’s look a little deeper into the bad (and good) things about this new engine, which rumor has it that Detroit spent a billion dollars developing.

Now, what I find strange, is the aluminum water manifold is within a quarter-inch of the exhaust manifold. The old rule in engine building is that aluminum expands and contracts much faster than cast iron, so it should only be used for covers. Exhaust  manifolds can get cherry-red pulling a mountain, so there is a lot of heat being generated there, which is also being transferred to the water manifold, no doubt. The water manifold also holds the EGR cooler, which is stainless steel.

manifolds can get cherry-red pulling a mountain, so there is a lot of heat being generated there, which is also being transferred to the water manifold, no doubt. The water manifold also holds the EGR cooler, which is stainless steel.

The picture below of the water manifold gasket clearly shows the failure causing the coolant leaks. This is a major repair – especially since the rocker assembly housing was cracked and must be replaced, too. Something else I see that has me concerned is there are no cam bearings in the aluminum rocker assembly on the DD15. Detroit considers this rocker housing to be a wear-item, however it’s $1,600 to replace! Now, with no cam bearings, on a 50,000-mile oil change, there is  already visible wear on the cam journal – enough that we now must replace the cams because a new rocker assembly is being installed.

already visible wear on the cam journal – enough that we now must replace the cams because a new rocker assembly is being installed.

The estimate on this repair is 33 hours, and that is according to an SRT manual. SRT stands for Standard Repair Time, which is usually low, because the engines the OEM’s use to establish these times are new – no dirt, rust or broken bolts to contend with, like on a typical repair of this nature. This engine also has a new style of camshaft which is hollow – not necessarily a bad thing (they are very lightweight) – but the lobes are not machined from steel billet, which concerns me a bit.

John Walko, our mechanical engineer, really likes the DD15 engine, so I will let him explain the features he likes: There are numerous things that I like a about the DD15; it is a truly modern low-friction high-efficiency engine. The camshafts are of a modular design, meaning that the lobes are ground separately from the shaft. The lobes are then affixed to the hollow shaft and then  the shaft is expanded with hydraulic pressure to create an interference (force) fit between the lobes and the shaft. The result is a durable part that has about half of the rotating mass of a conventional camshaft.

the shaft is expanded with hydraulic pressure to create an interference (force) fit between the lobes and the shaft. The result is a durable part that has about half of the rotating mass of a conventional camshaft.

The gear train that drives the cams on the DD15 is comprised of gears that are about half the width and weight of normal gears, and look like they were made by a clock maker (they are very precise). The benefits here are two-fold: less friction due to less surface area on each gear tooth and, again, less rotating mass. Keep in mind that it takes fuel to make everything go around, but with low-friction piston and ring assemblies, along with a variable-speed water pump, you will use less of it.

I have yet to see the bottom end of one of these DD15 engines apart (that’s probably a good thing), but I’m sure that I will find more cool stuff there, too. Factory tuning has this engine making peak torque at 975 RPM, which I find amazingly-low. I believe that as we get to diminishing returns in regard to internal combustion efficiency, slowing down the RPMs will be the next frontier – and Detroit already seems to be on to this. These engines also respond quite well to our tuning and benefit  greatly from our new “Soot Separator” EGR filtration system. What’s not to like?

greatly from our new “Soot Separator” EGR filtration system. What’s not to like?

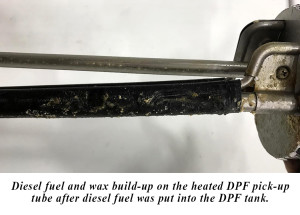

WARNING: Be careful with the DEF (Urea) tank on your 2011 semi or pickup truck – it is not compatible with diesel fuel. Never install or allow anyone to put diesel fuel into the DEF tank. If this happens, and diesel fuel gets into your DEF tank, the urea will turn into a wax – like ear wax – yes, the stuff your body produces in your ear canal. What a disaster this is to the entire emissions system – and costly to repair.

If this occurs, as it recently did with one of our customers, here is what we had to do to correct the problem: 1) Remove the DEF tank and clean out all the wax material; 2) Replace the heating and urea pick-up assembly; 3) Flush the lines, which are heated, to the doser valve; 4) Replace the doser valve and the electric pump; 5) Force a re-gen, dyno test, and then do a long test drive to make sure the emissions system is working properly. Hot soapy water will not remove the wax material. This is a time-consuming and expensive  repair, so avoid it, if possible.

repair, so avoid it, if possible.

If diesel fuel mistakenly gets into your DEF tank, give us a call. We can help you get your truck back on track and running smooth. For more details about our products and/or services, call (724) 360-4080 or visit us online at www.pittsburghpower.com today.